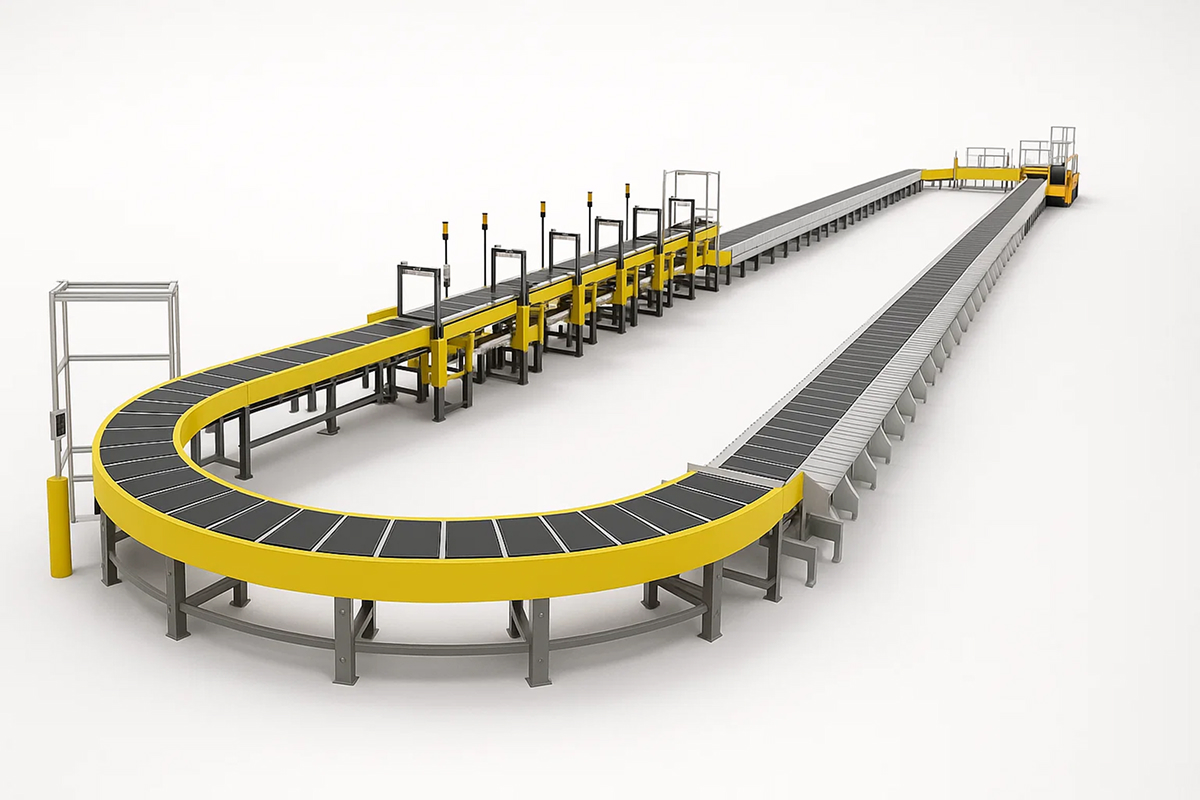

System Introduction

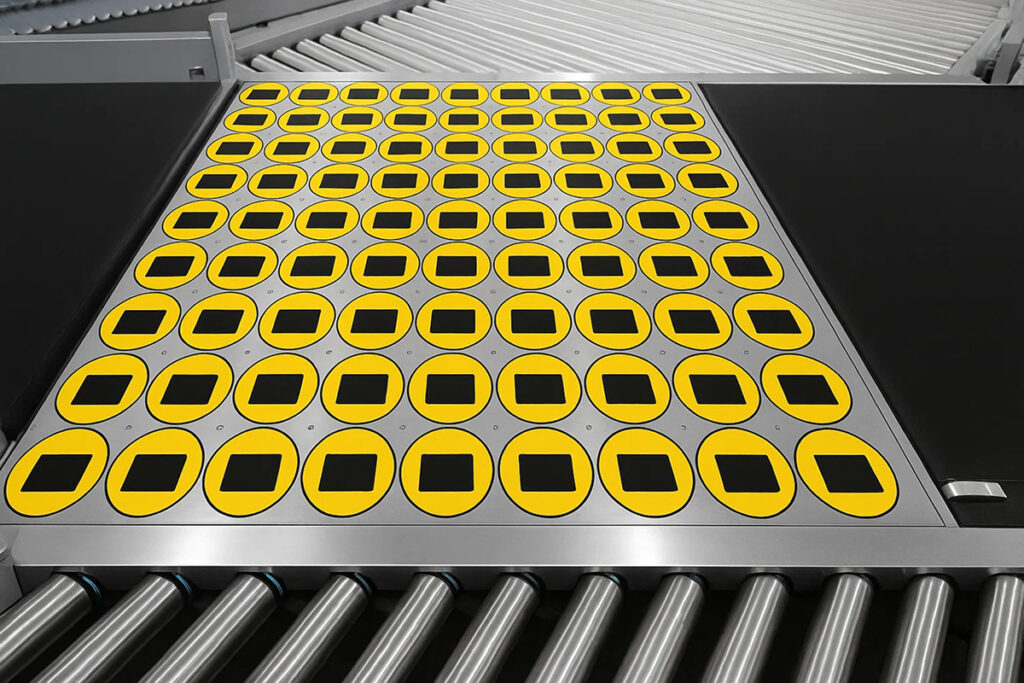

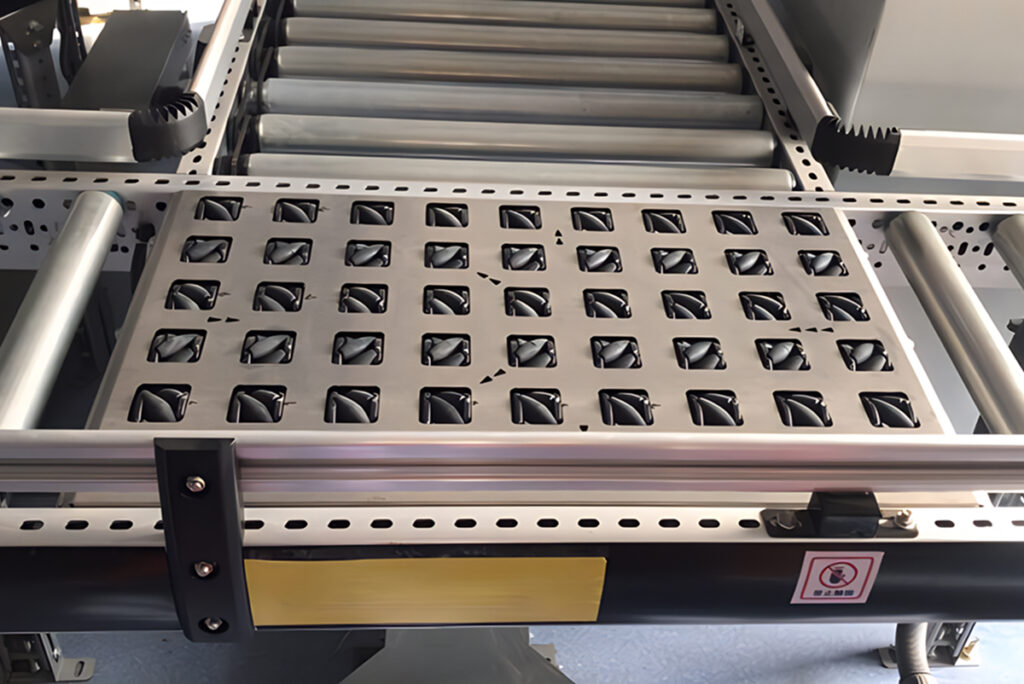

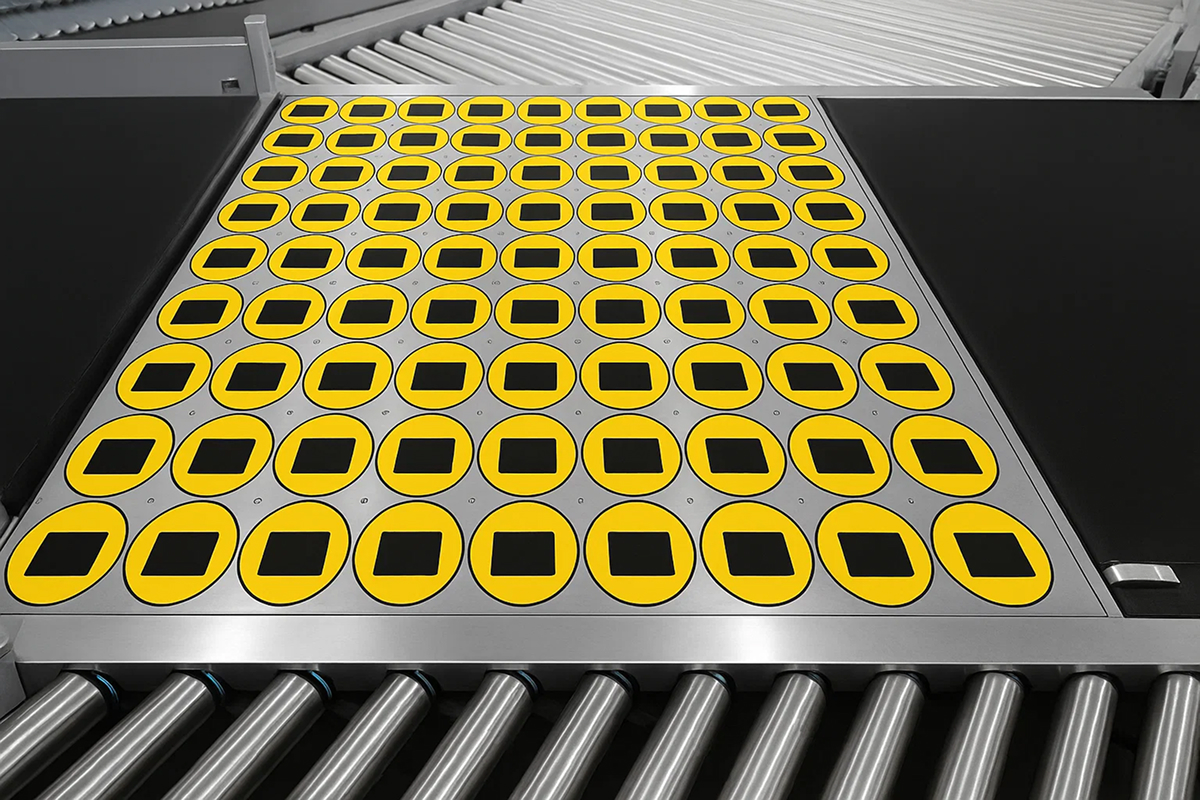

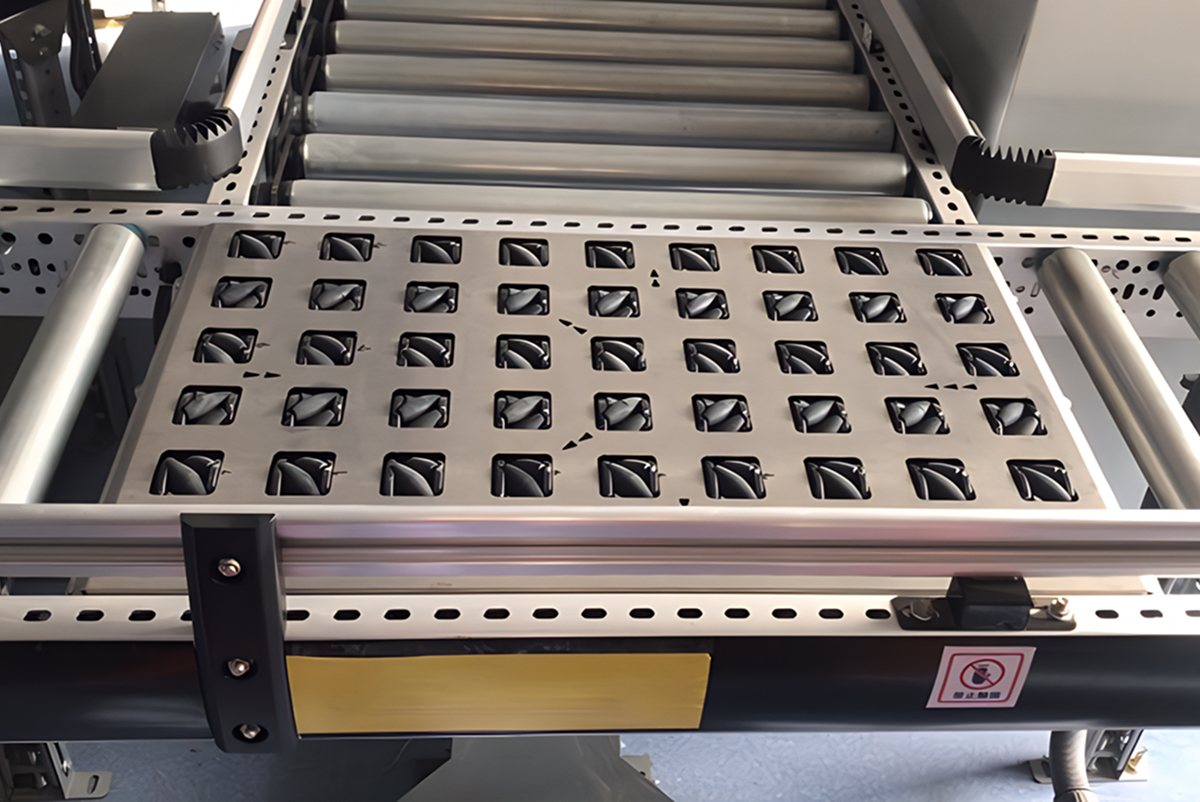

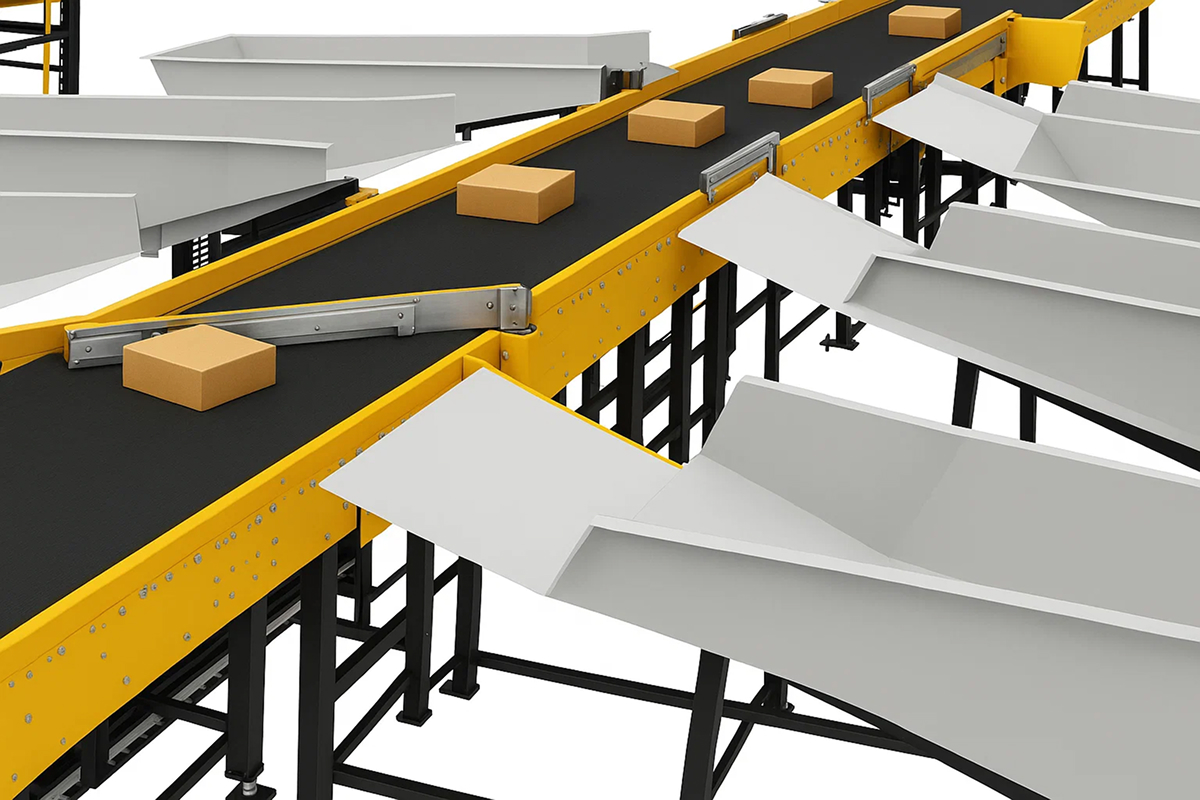

Wheel Sorters are a dynamic solution for medium-speed parcel and carton sorting in logistics and distribution systems. Using powered wheels mounted on pivoting beds or belts, items are diverted at angles—usually 30° or 45°—to designated chutes or conveyor lines.

Achieve superior sorting performance with Leador Tech’s robust Wheel Sorters, engineered for high-speed, high-capacity, and reliable diversion of a vast range of items.

Application Scenarios

E-commerce Fulfillment

Rapid sorting of uniform parcels, return goods, and pre-packed SKUs

Postal & Courier Centers

Inline diversion of letters, envelopes, and small packages compact modular

Retail Distribution Hubs

Downstream product sorting to store-specific shipping lanes

Book & Publishing Logistics

High-volume, low-friction redirection of boxed goods

Manufacturing Lines

Sorting of component trays and boxed compact modularsubassemblies

Technical Specifications

|

Parameter

|

Value

|

|---|---|

|

Max Sort Rate |

4,500 items/hour |

|

Divert Angle |

30° / 45° |

|

Package Weight |

Up to 50 kg |

|

Conveyor Speed |

0.8–1.2 m/s |

|

Motor Type |

Servo / AC drive motors |

|

Control Integration |

PLC + SCADA / WCS compatible |

|

Max Noise Level |

≤ 72 dB |

Applications & Case Studies

Discover how Leador has empowered businesses to achieve their logistics goals. Explore our detailed case studies showcasing real-world implementations and measurable results