Product Overview

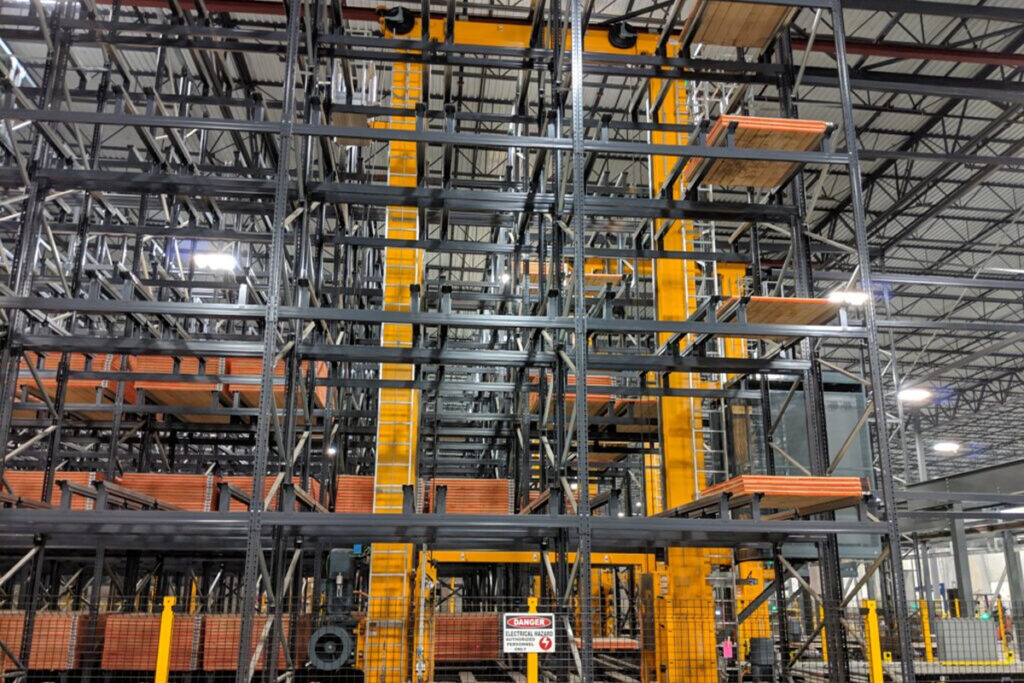

Shuttle Systems are automated storage systems utilizing battery-powered shuttles that move horizontally within racking channels to store and retrieve goods. Operating independently from cranes, these shuttles can access multiple pallets deep per channel, dramatically increasing the storage density compared to single-deep racking systems.

LEADOR’s shuttle portfolio includes:

Introduction & Core Benefits

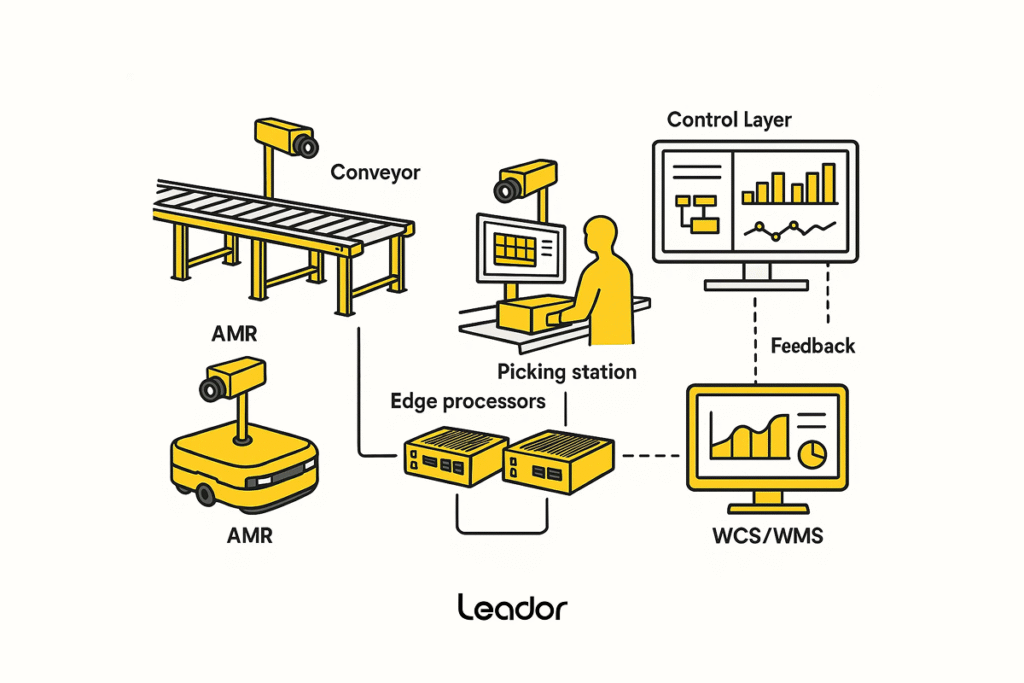

Leador Tech’s Shuttle Systems are advanced Automated Storage and Retrieval Systems (AS/RS) that utilize robotic shuttles to independently move horizontally within storage aisles and retrieve or deposit individual cartons, totes, or trays. Unlike traditional stacker cranes which operate on a single crane per aisle, shuttle systems can deploy multiple shuttles per level or aisle, enabling parallel operations and significantly higher throughput. Our solutions offer unparalleled flexibility in storage depth (single, double, or multi-deep), making them ideal for high-volume operations with diverse SKU profiles in e-commerce, apparel, food & beverage, and manufacturing.System Architecture

01. Robotic Shuttles

02. Multi-Level Racking Structure

03. Vertical Lifts / Conveyors

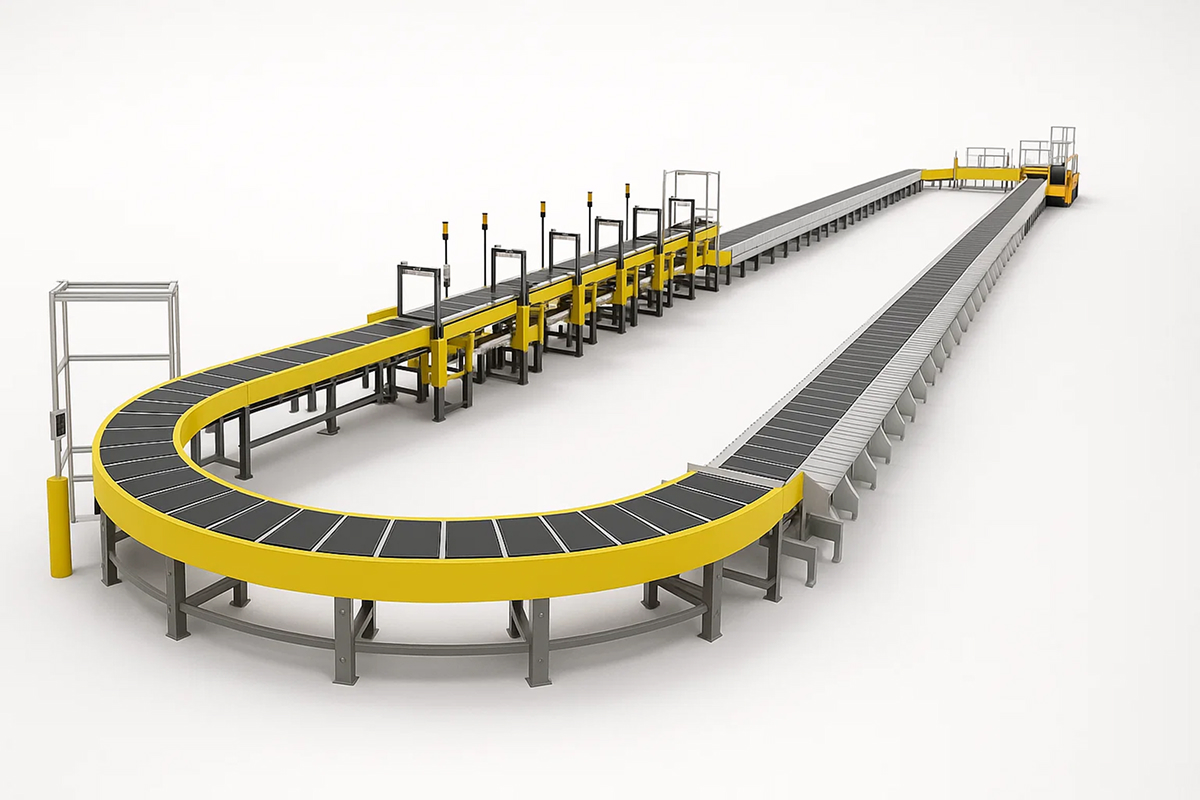

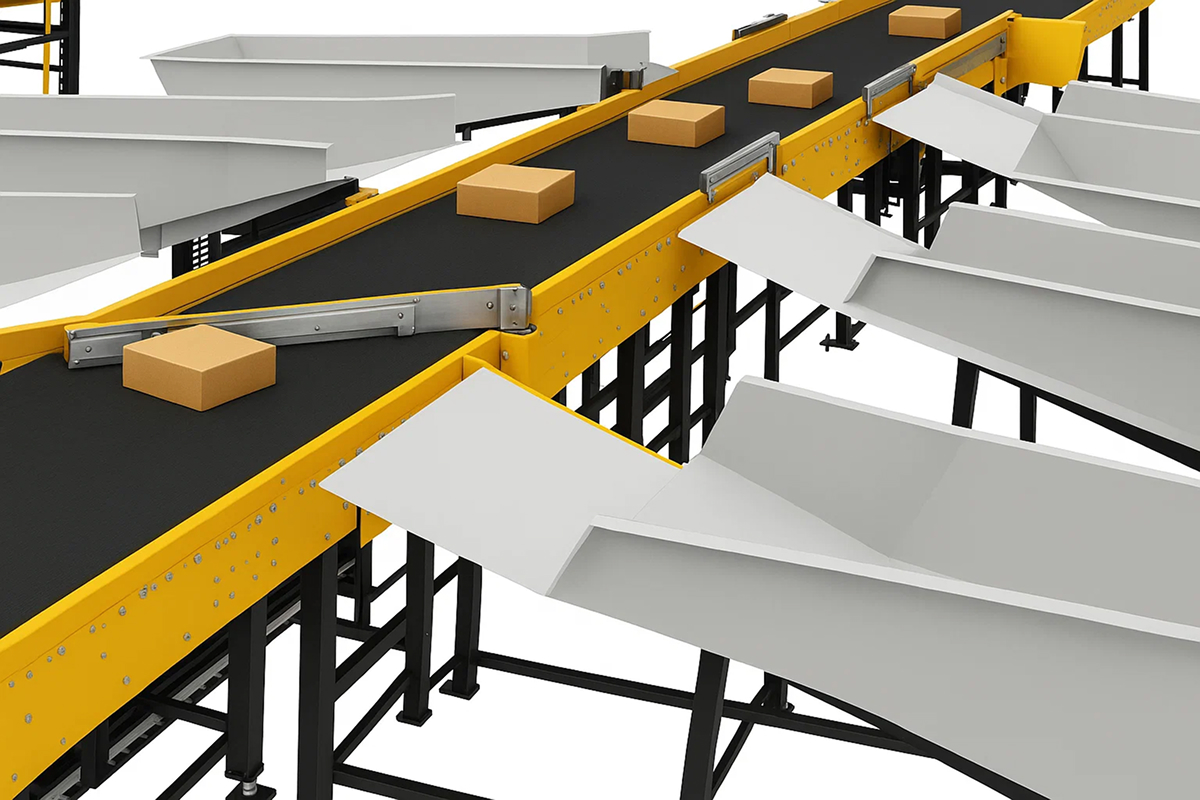

04. Conveyor Systems

05. Control Systems (WCS/PLC)

Application Scenarios

Warehousing

Maximizes cubic storage in frozen environments

E-commerce

High throughput for bin picking and returns handling.

Manufacturing

Real-time part storage and retrieval to assembly lines.

Food & Beverage

Supports FIFO storage logic for perishable goods.

Technical Specifications

|

Parameter

|

Value Range

|

Engineering Notes

|

|---|---|---|

|

Channel Depth |

3 – 20 pallets |

Depending on shuttle type & rack structure |

|

Load Capacity |

30 – 1,500 kg |

Lightweight bins to heavy unit loads |

|

Speed (Loaded) |

Up to 1.5 m/s |

Depending on payload |

|

Lift Speed |

30 – 80 m/min |

Affects multi-level responsiveness |

|

Charging Time |

1 – 2 hours |

With fast-charging Li-ion systems |

|

Operating Temperature |

-30°C to +50°C |

Cold storage-compatible designs available |

|

Accuracy |

±10 mm |

Sensors with real-time positioning feedback |

Applications & Case Studies

Discover how Leador has empowered businesses to achieve their logistics goals. Explore our detailed case studies showcasing real-world implementations and measurable results