System Introduction

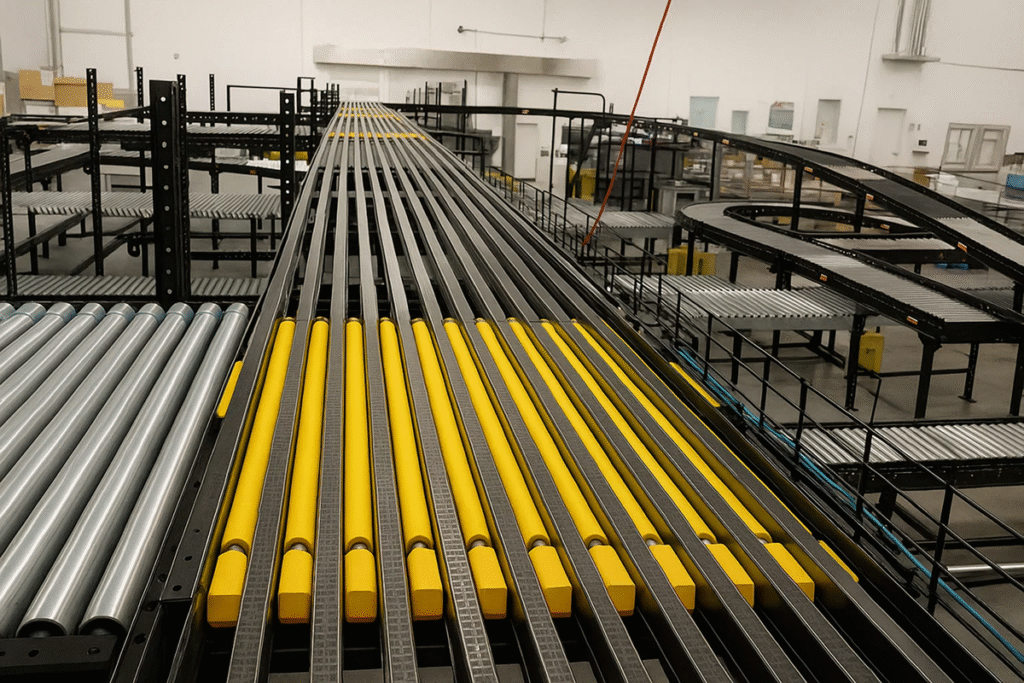

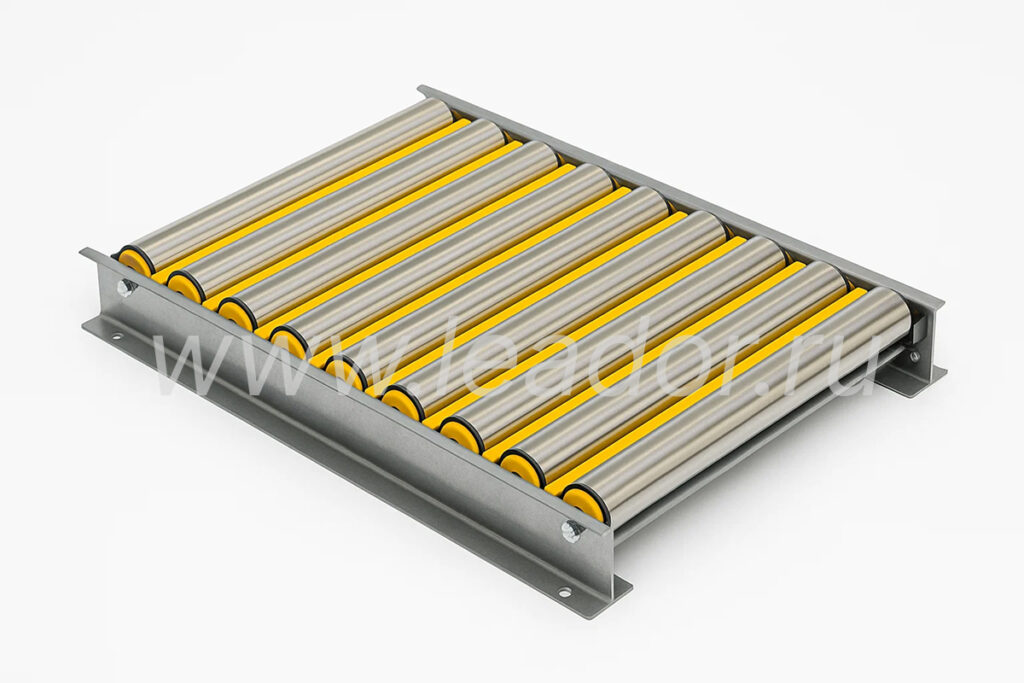

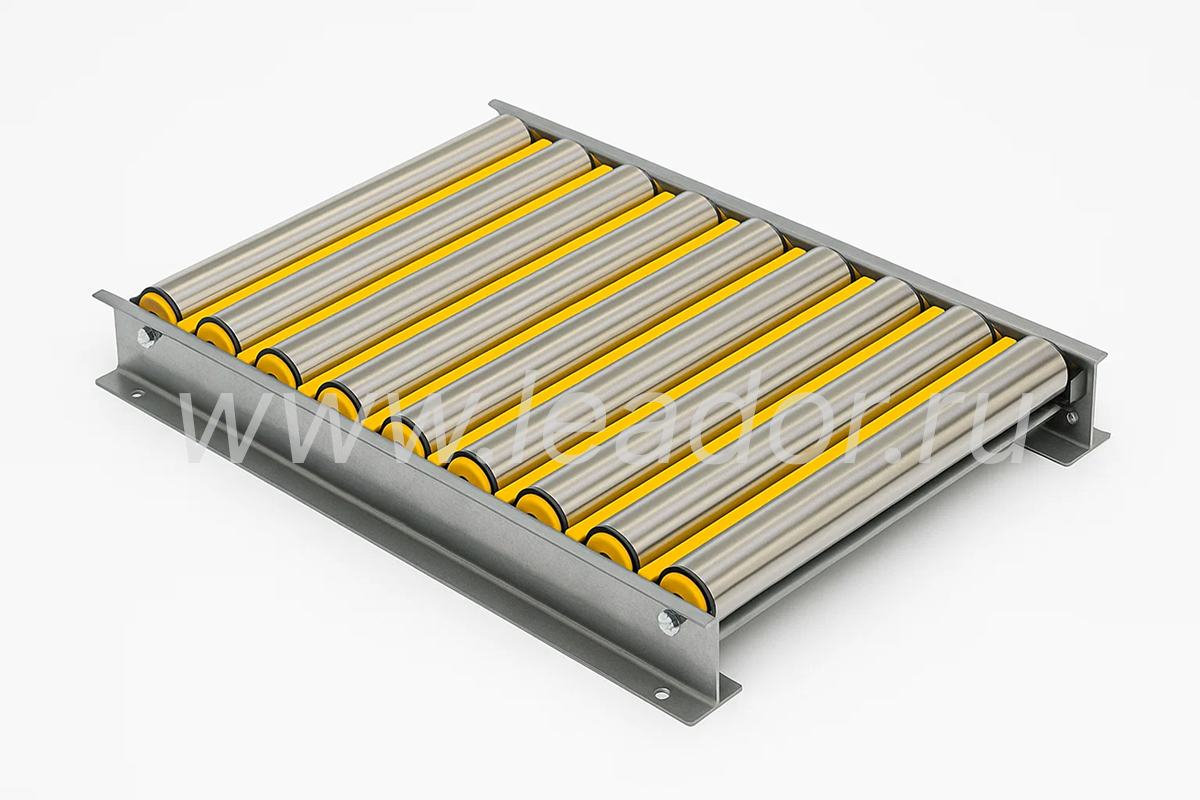

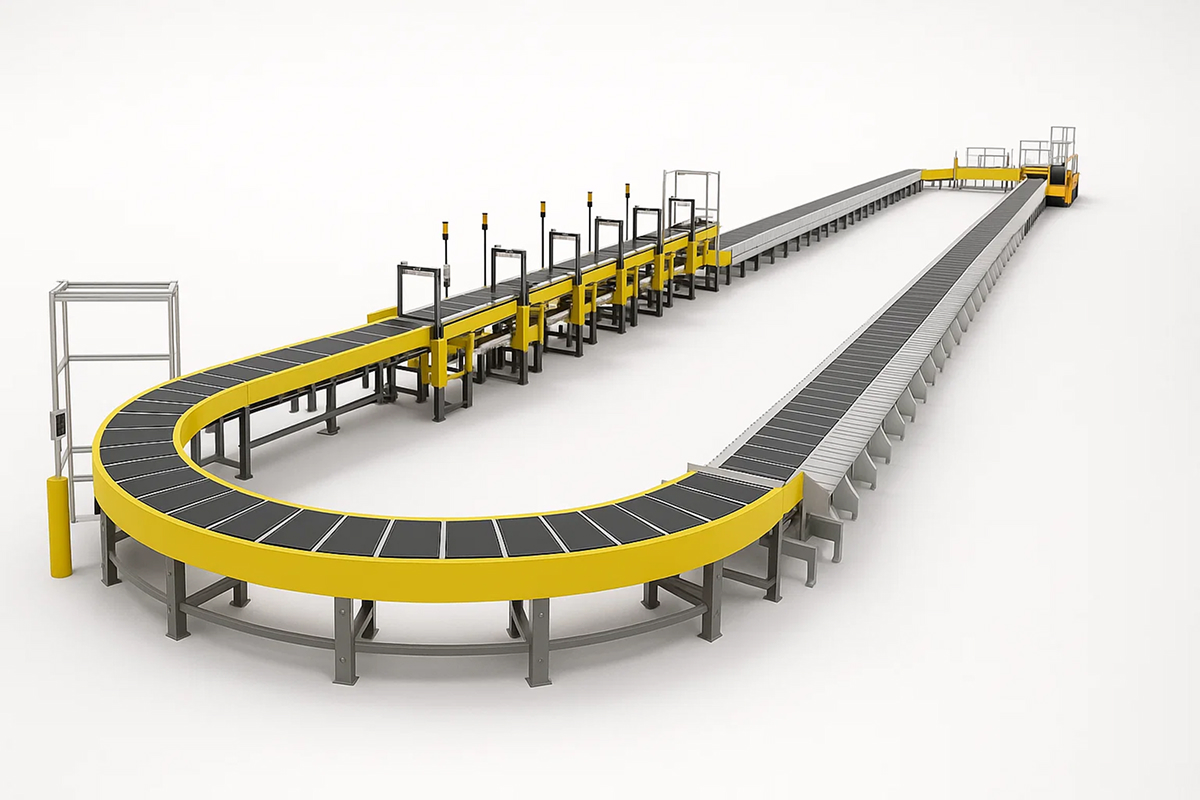

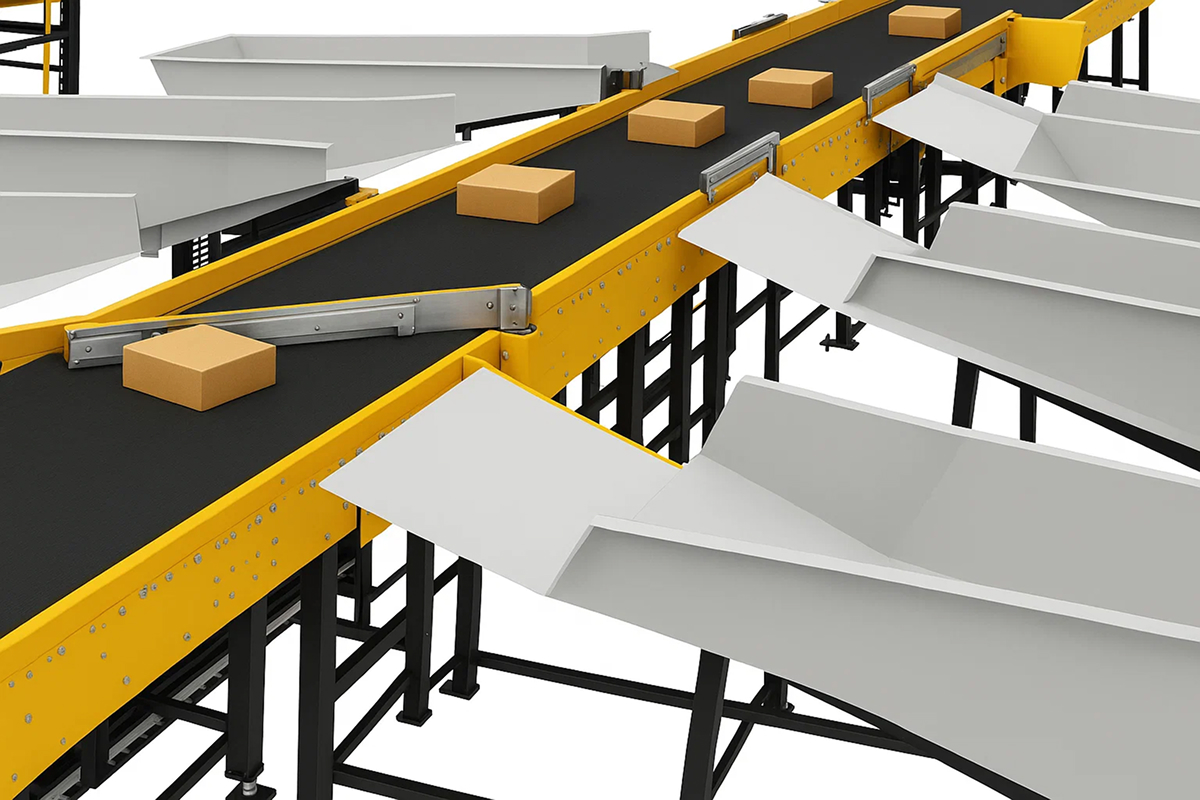

Pop-up Sorters are compact, modular, and highly adaptable sortation devices that use vertical lifting mechanisms to raise rollers, belts, or wheels at sorting junctions. When activated, these units “pop up” from beneath the conveyor line to redirect items along the desired outbound path — either at a 30° or 90° angle, depending on the layout. This type of system is often installed at key diversion points along a main conveyor, offering reliable on-the-fly item redirection without halting upstream flow.

Known for their space-efficient design and versatility, pop-up sorters are ideal for applications that require selective lane switching, destination-based dispatching, or infeed/outfeed zoning within compact facilities. They’re commonly used in e-commerce parcel handling, pharmaceutical packaging, grocery distribution, and reverse logistics operations.

Pop-up modules can work as standalone units or be integrated into conveyor matrix layouts, and are often controlled via PLC systems, ensuring accurate, synchronized switching.

Application Scenarios

E-commerce Fulfillment

Fast, inline redirection of parcels based on order ID or shipping method. Boosts picking line speed sortation.

Pharma & Cosmetics

Precise and gentle sorting for small, sensitive products in cleanroom or GMP environments.

Retail Distribution

Modular diverting for outbound dispatch in DCs. Supports case or tote sortation by store or category.

Returns Processing

Dynamic sorting of return goods based on scanning, condition, or restocking status.

Food & Beverage Lines

Inline carton diversion for packing, labeling, or palletizing zones without halting flow.

Technical Specifications

|

Parameter

|

Value

|

|---|---|

|

Max Throughput |

2,500 – 5,000 pcs/hour per unit |

|

Actuation Speed |

< 0.5 seconds |

|

Item Size Range |

200 × 200 mm to 800 × 600 mm |

|

Max Item Weight |

Up to 35 kg |

|

Divert Angles |

30°, 45°, 90° |

|

Drive Type |

Electric / Pneumatic / Servo |

|

Control Interface |

PLC / Sensor Trigger |

Applications & Case Studies

Discover how Leador has empowered businesses to achieve their logistics goals. Explore our detailed case studies showcasing real-world implementations and measurable results