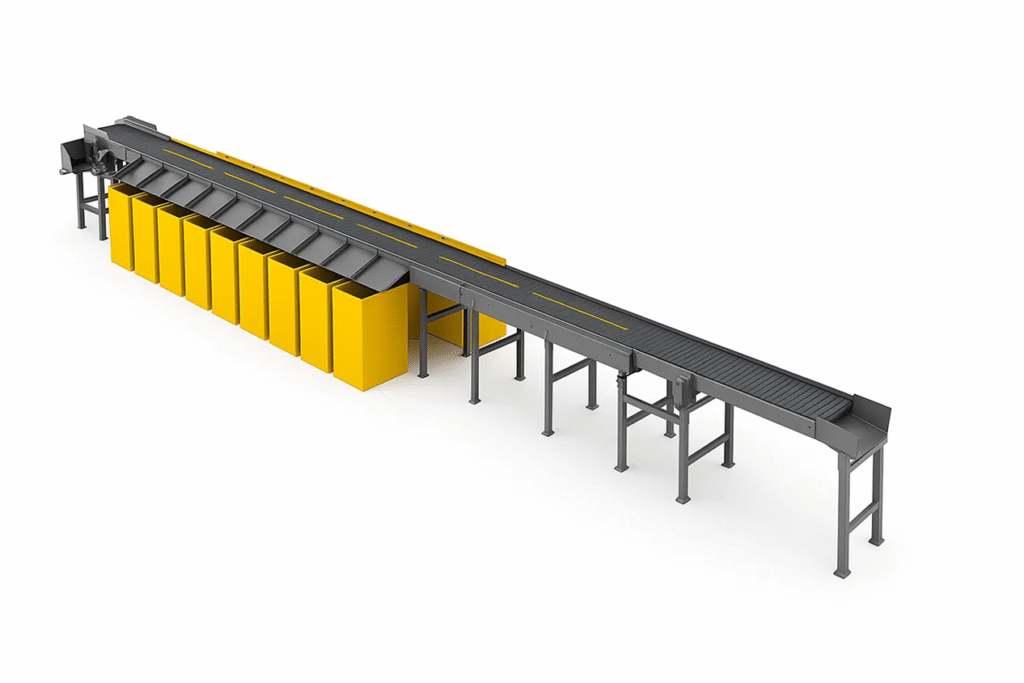

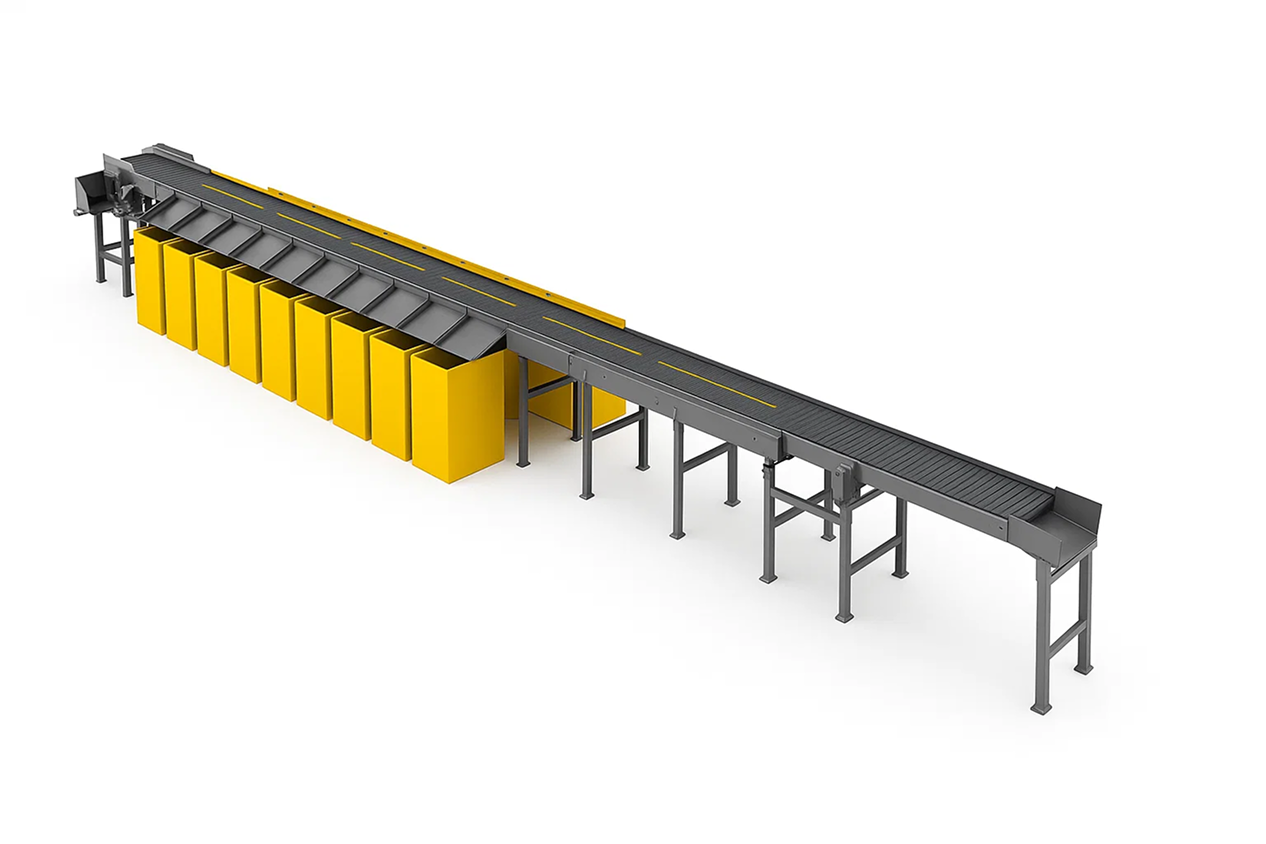

System Introduction

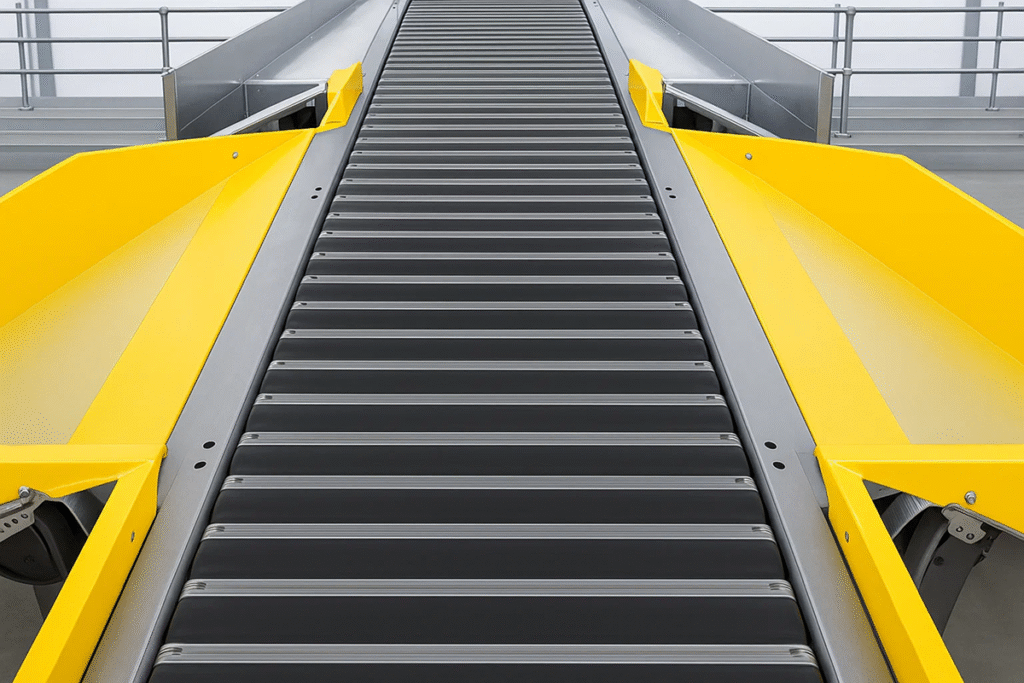

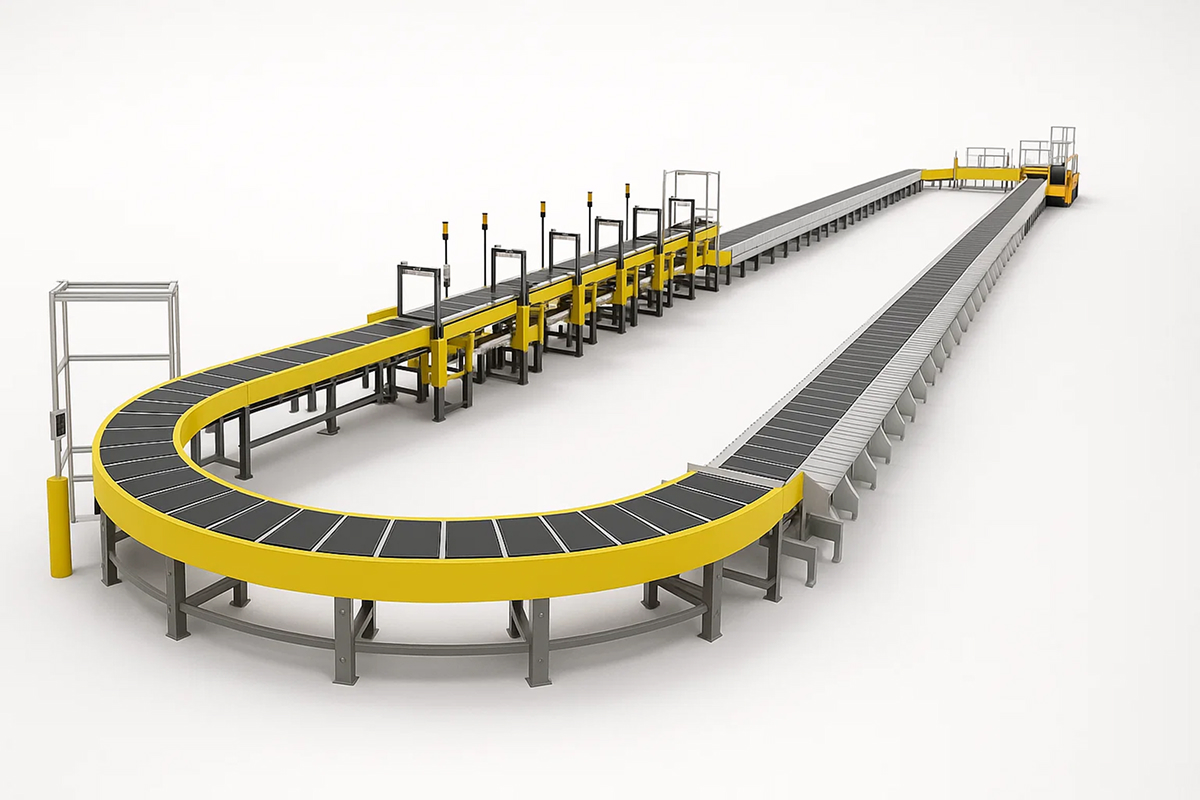

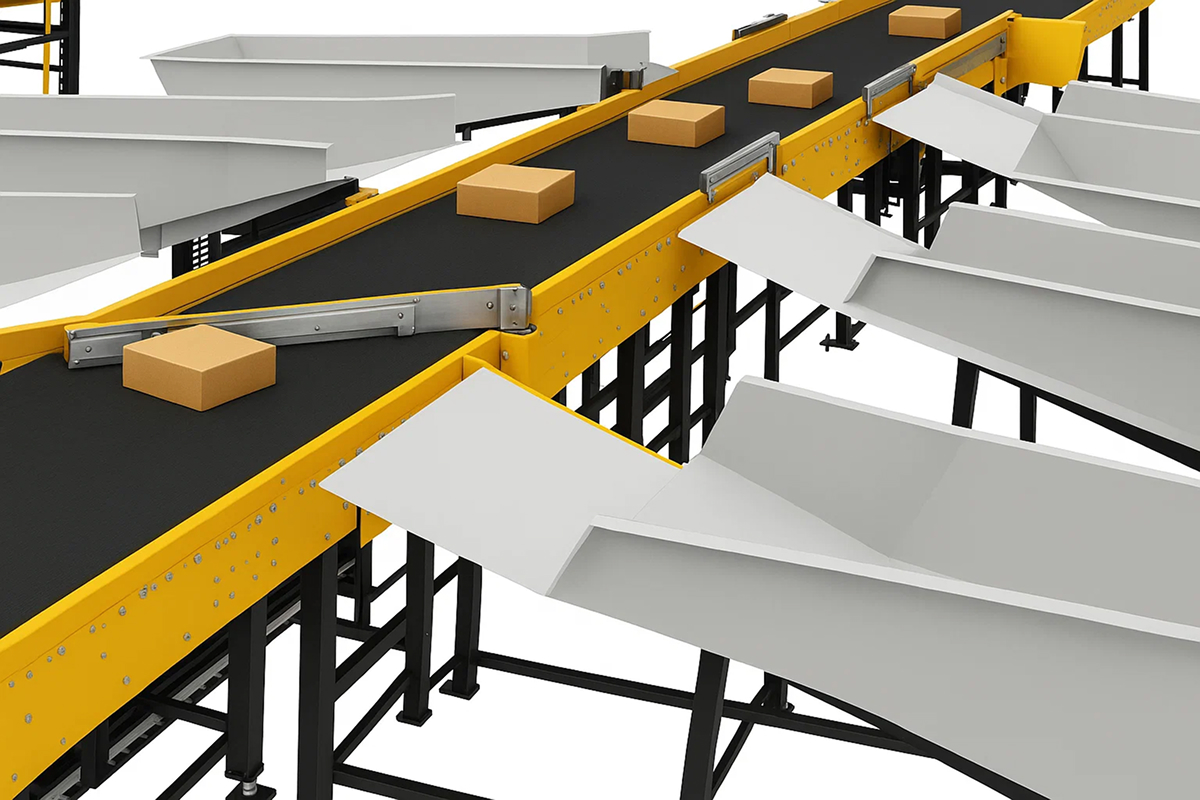

The Narrow Belt Sorter is a versatile sortation solution designed to handle medium to large cartons and totes with high-speed directional changes. It uses a series of narrow-width conveyor belts, with pop-up rollers or divert shoes positioned between them, to achieve precise 30° or 90° product diversion at high throughput.

Whether you’re managing a high-throughput e-commerce line, a busy postal center, or a retail distribution hub, the narrow belt sortation system brings multi-angle sorting precision, quiet operation, and layout flexibility to your logistics workflow.

Application Scenarios

Retail Distribution

Handles sortation of cartons by store, SKU, or region with efficient lane routing.

E-commerce & 3PL

Ideal for mid-to-high throughput parcel sortation with compact modular lines.

FMCG Warehouses

Transport and sort beverage cartons or containers at angle-diverted stations.

Postal & Parcel Hubs

Accurate sortation of uniform and irregular packages by destination code or zone.

Manufacturing Lines

Inline routing of boxed components, finished goods, or returned materials.

Technical Specifications

|

Parameter

|

Value

|

|---|---|

|

Max Throughput |

Up to 6,000 items/hour |

|

Divert Angles |

30° or 90° |

|

Load Capacity |

50 kg per item (varies by config) |

|

Belt Width |

100–200 mm per lane |

|

Min Package Size |

200 x 150 mm |

|

Control Mode |

PLC or integrated WCS |

|

Noise Level |

< 70 dB |

Applications & Case Studies

Discover how Leador has empowered businesses to achieve their logistics goals. Explore our detailed case studies showcasing real-world implementations and measurable results