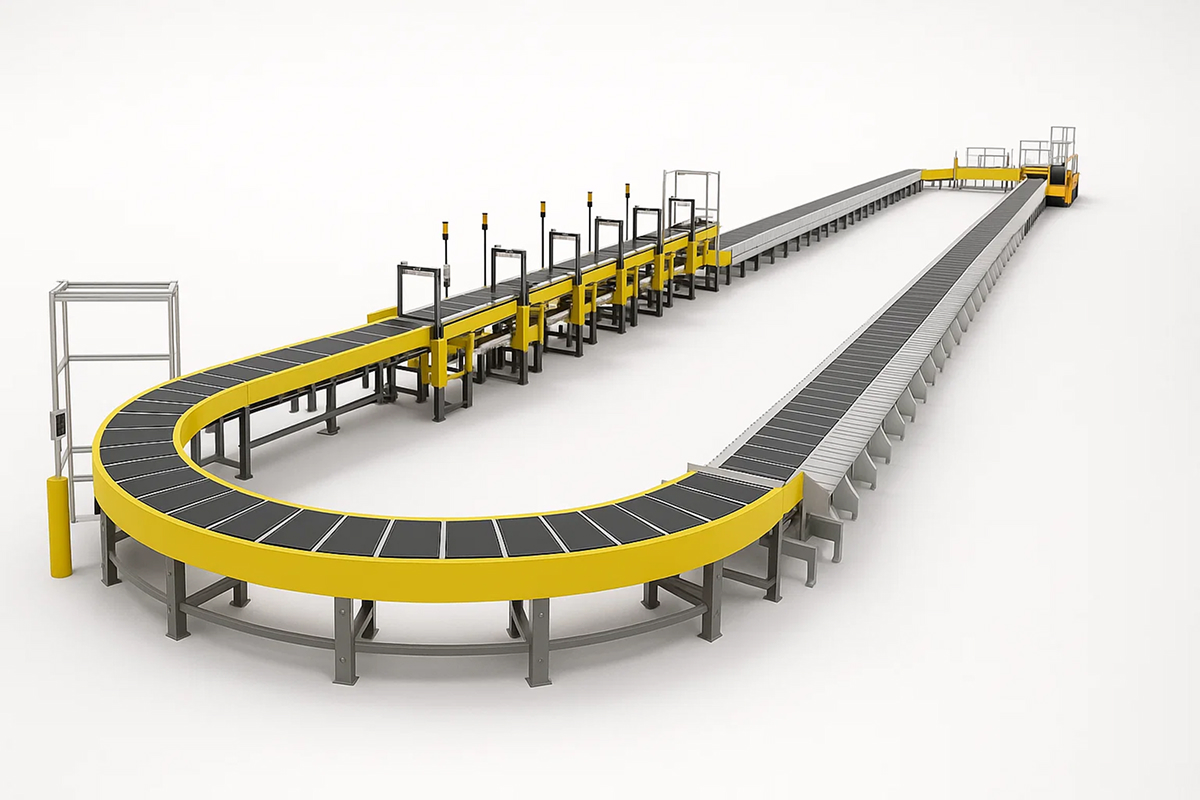

Product Overview

Telescopic conveyor systems are designed specifically to automate the process of loading and unloading goods from trucks, containers, or trailers. These conveyors feature extendable booms that can slide in and out of vehicles, minimizing the need for manual labor and reducing loading time.

Introduction & Core Benefits

Leador Tech’s Telescopic Conveyors, often referred to as boom conveyors or extendable conveyors, are specialized material handling units designed to extend and retract directly into the back of trailers, containers, and trucks. This unique capability eliminates the need for manual transport over long distances within the vehicle, allowing operators to load or unload packages, cartons, and loose items directly onto or off the conveyor belt at the point of origin or destination. Integrating seamlessly with your existing dock equipment, our telescopic conveyors are essential for any operation seeking to maximize efficiency, reduce labor costs, and improve safety in high-volume shipping and receiving environments.Overhead Conveyor Types

01. Standard Telescopic Belt Conveyors

02. Telescopic Boom Conveyors with Accumulation

03. Telescopic Conveyors with Optional Features

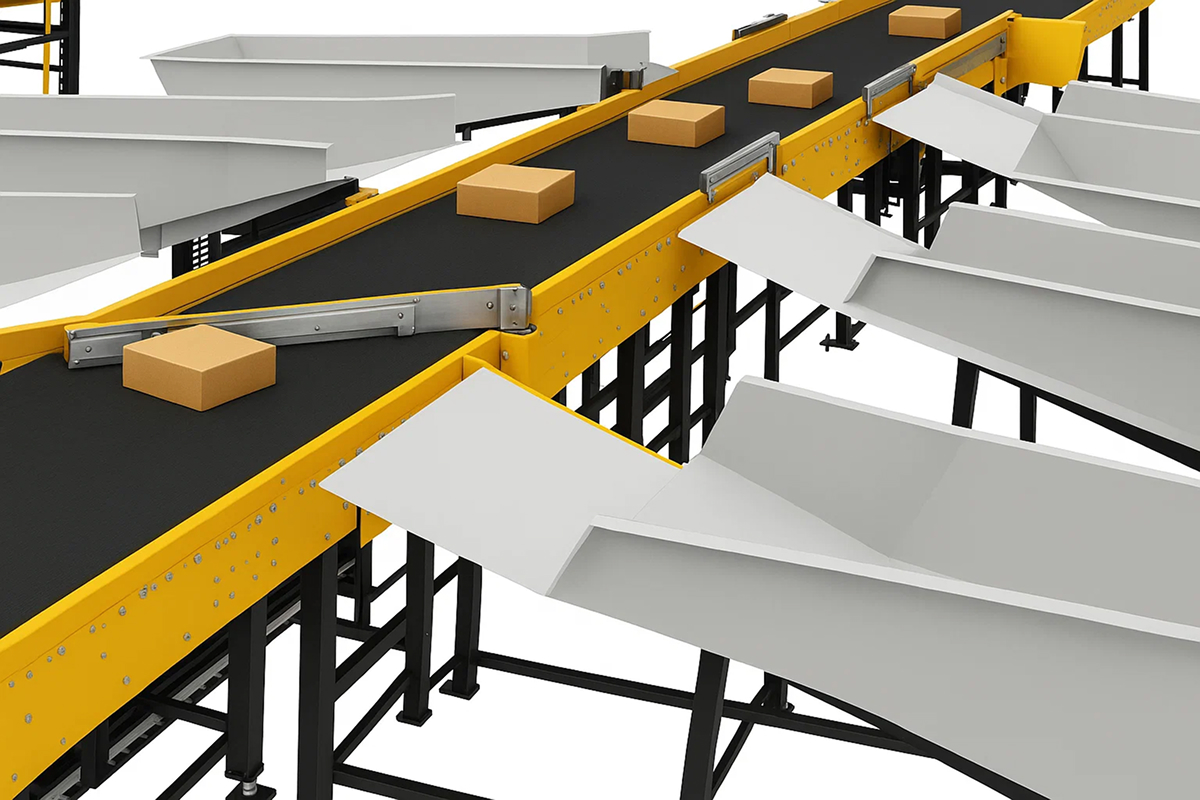

Application Scenarios

Parcel & Courier Hubs

Speed up trailer loading with fewer workers, lower risk.

E-commerce

Enable high-frequency truck turnover with minimal delay.

Cross-Docking Facilities

Streamline throughput between inbound and vehicles

Third-Party Logistics

Increase turnaround on mixed-fleet operations.

- Belt Material: Durable, low-friction belts (e.g., PVC, rubber) suitable for various package types and environments.

- Drive System: Robust electric motors and gear reducers for smooth extension/retraction and belt movement.

- Controls: User-friendly operator interface, emergency stops, safety light curtains, and integration with PLC/WCS.

- Lighting & Ventilation: Integrated LED lights and optional fans for improved visibility and air circulation inside the vehicle.

- Dock Levelers & Seals: Ensure a seamless transition between the dock and the vehicle

- Integrated Sensors: Detect package presence, monitor boom position, and ensure safe operation.

Technical Specifications

|

Parameter

|

Value Range

|

Engineering Notes

|

|---|---|---|

|

Max Extension Length |

6–20 m |

Choose based on trailer/container depth |

|

Belt Width |

600 – 1,000 mm |

Match to load type and facility layout |

|

Load Capacity |

Up to 50 kg/m |

Suitable for cartons, totes, polybags |

|

Belt Speed |

0.2 – 0.5 m/s |

Adjustable with inverter |

|

Elevation Range |

± 300 mm |

Height range varies by model |

|

Motor Power |

1.5 – 4.0 kW |

Depends on extension force and belt load |

Applications & Case Studies

Discover how Leador has empowered businesses to achieve their logistics goals. Explore our detailed case studies showcasing real-world implementations and measurable results