Product Overview

Overhead conveyors are suspended material handling systems used to transport items along a designated path above ground-level operations. These systems are ideal for facilities aiming to optimize space utilization while enabling continuous movement of light-to-medium load items. LEADOR offers various overhead conveyor types including enclosed track, I-beam, and power & free systems, tailored for a range of industries from apparel to automotive.

Introduction & Core Benefits

Leador Tech’s Overhead Conveyor Systems are specialized material handling solutions that transport products and components via carriers suspended from an overhead track. Unlike floor-based conveyors, these systems ingeniously utilize the often-unused vertical space, providing unimpeded floor access and significantly reducing congestion in busy operational areas. Our robust overhead conveyors offer continuous, precise, and flexible material flow for a vast array of applications, from intricate assembly processes and painting lines to buffering and inter-departmental transfers in automotive, electronics, apparel, and general manufacturing industries.Overhead Conveyor Types

01. Overhead Chain Conveyors

02. Power & Free Conveyors

03. I-Beam Conveyors

Application Scenarios

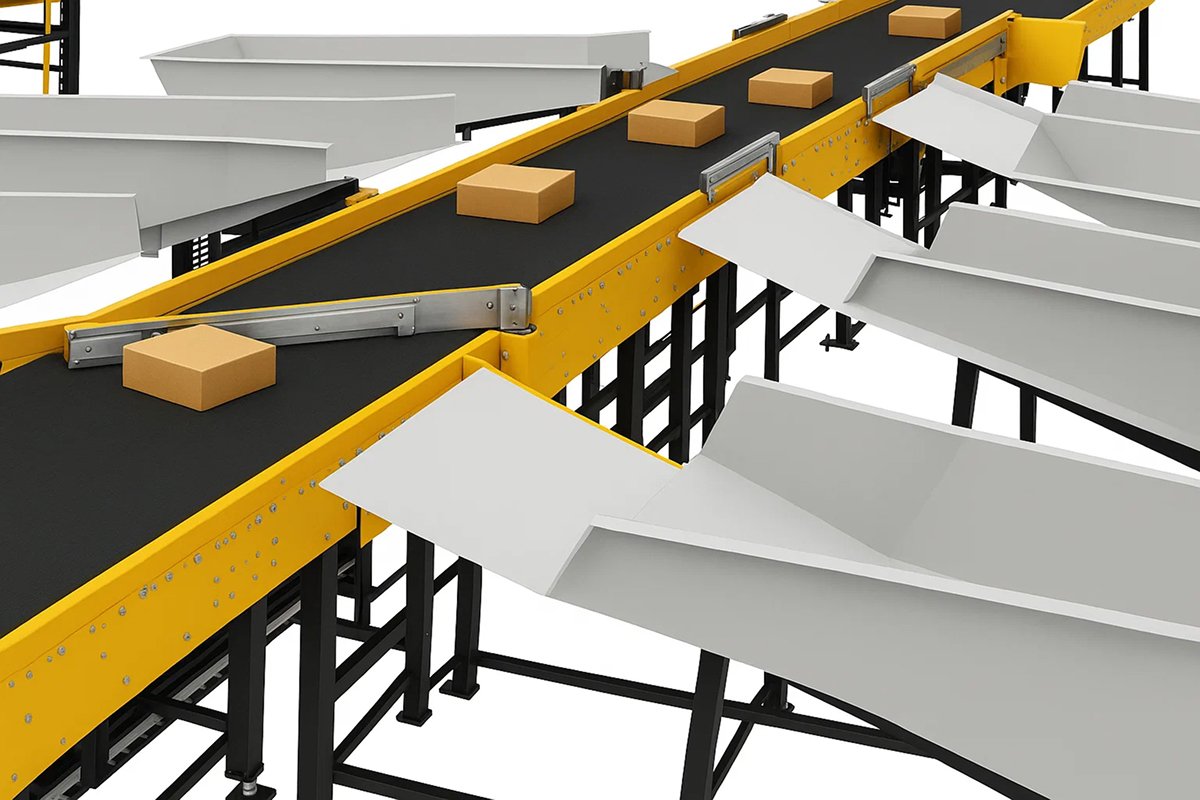

Distribution Centers

High-density garment hanging and sorting

Warehouses

Free up floor space, enable parcel flow

Manufacturing

Sanitary overhead product handling

Recycling

Safe overhead segregation of items

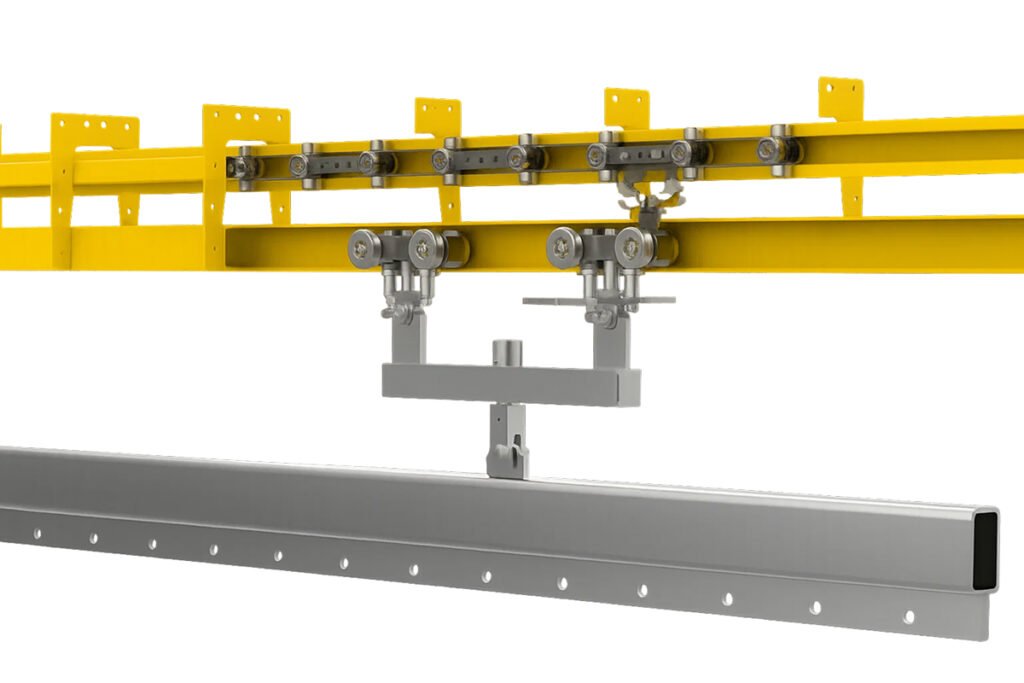

- Tracks/Rails: Modular, high-strength steel (e.g., enclosed track, I-beam) for various load capacities and routing.

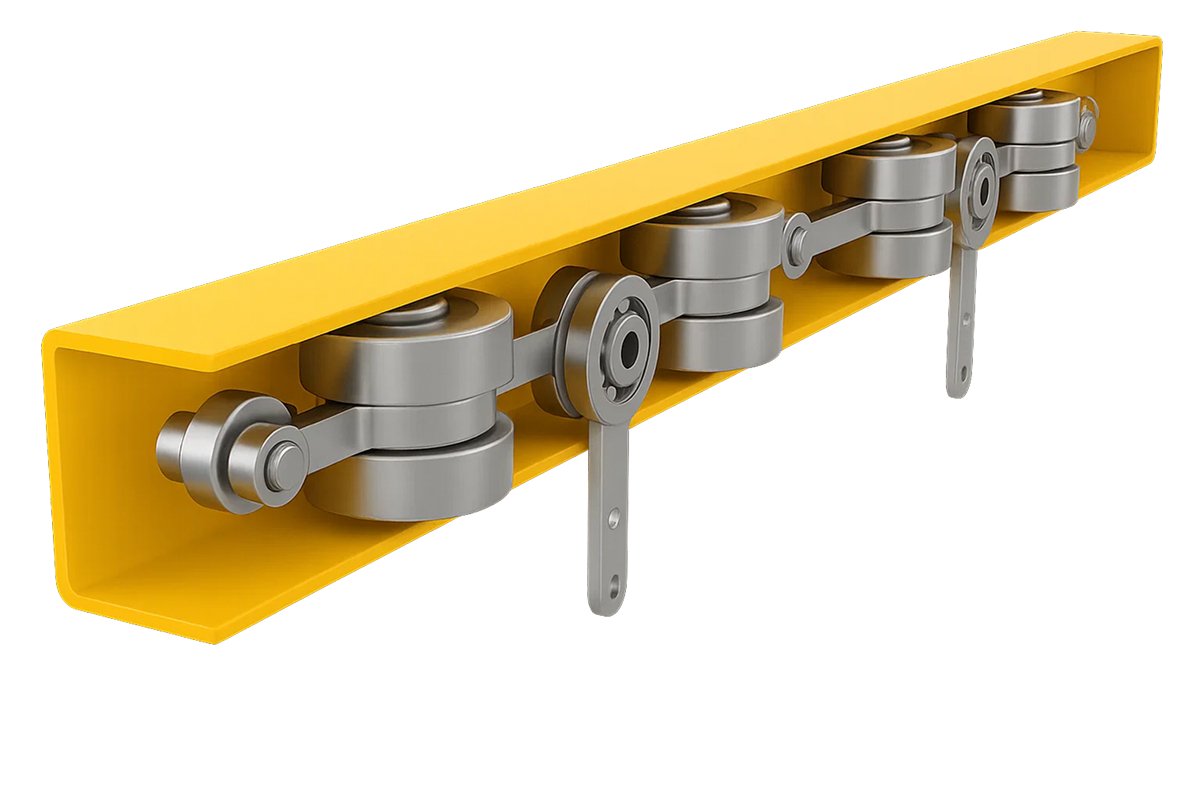

- Chains & Trolleys: Durable, wear-resistant chains and robust trolleys/carriers designed for specific loads and environments.

- Drive Units: Energy-efficient motors, gear reducers, and variable frequency drives (VFDs) for precise speed control and smooth acceleration/deceleration.

- Custom Carriers & Fixtures: Engineered to securely hold and transport diverse products (hooks, baskets, specialized jigs).

- Switches & Accumulators (for Power & Free): Automated mechanisms for diverting, merging, accumulating, and releasing carriers.

- PLC Control Systems: Intelligent control panels and software for automated routing, sequencing, tracking, and system diagnostics.

Technical Specifications

|

Parameter

|

Value Range

|

Engineering Notes

|

|---|---|---|

|

Load Capacity |

10 – 300 kg per carrier |

Depends on trolley, carrier, and track design |

|

Speed |

0.2 – 1.5 m/s |

Adjustable with VFD or servo motor |

|

Track Material |

Steel, Aluminum |

Depends on load and corrosion environment |

|

Drive Power |

0.5 – 5.0 kW |

Selection based on length and load curve |

|

System Height |

Customizable |

Based on ceiling height and vertical routing needs |

Applications & Case Studies

Discover how Leador has empowered businesses to achieve their logistics goals. Explore our detailed case studies showcasing real-world implementations and measurable results