Product Overview

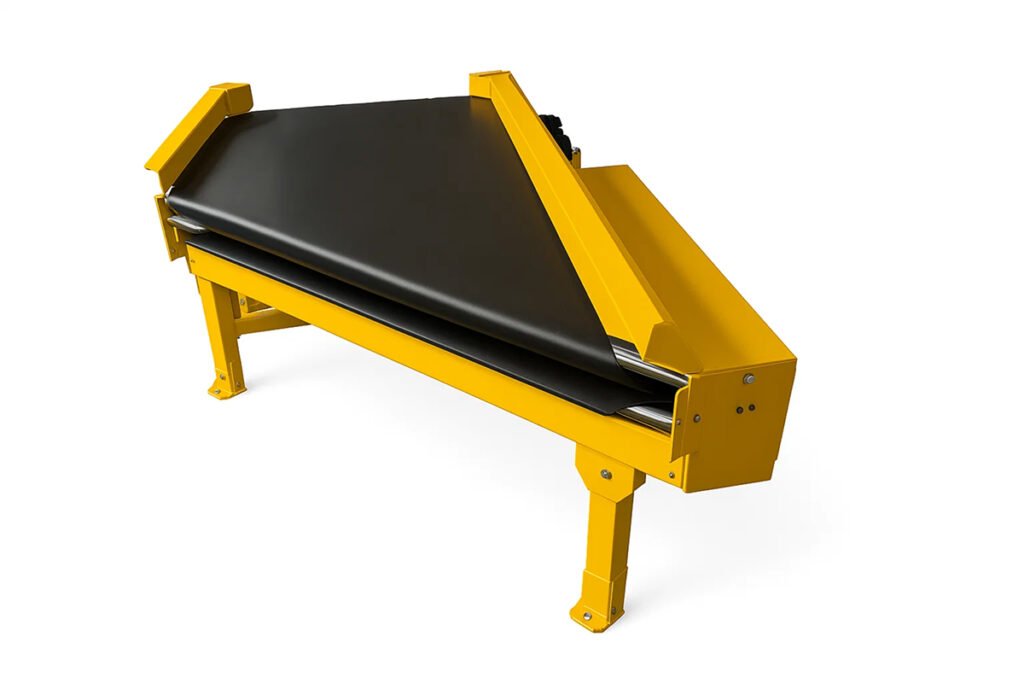

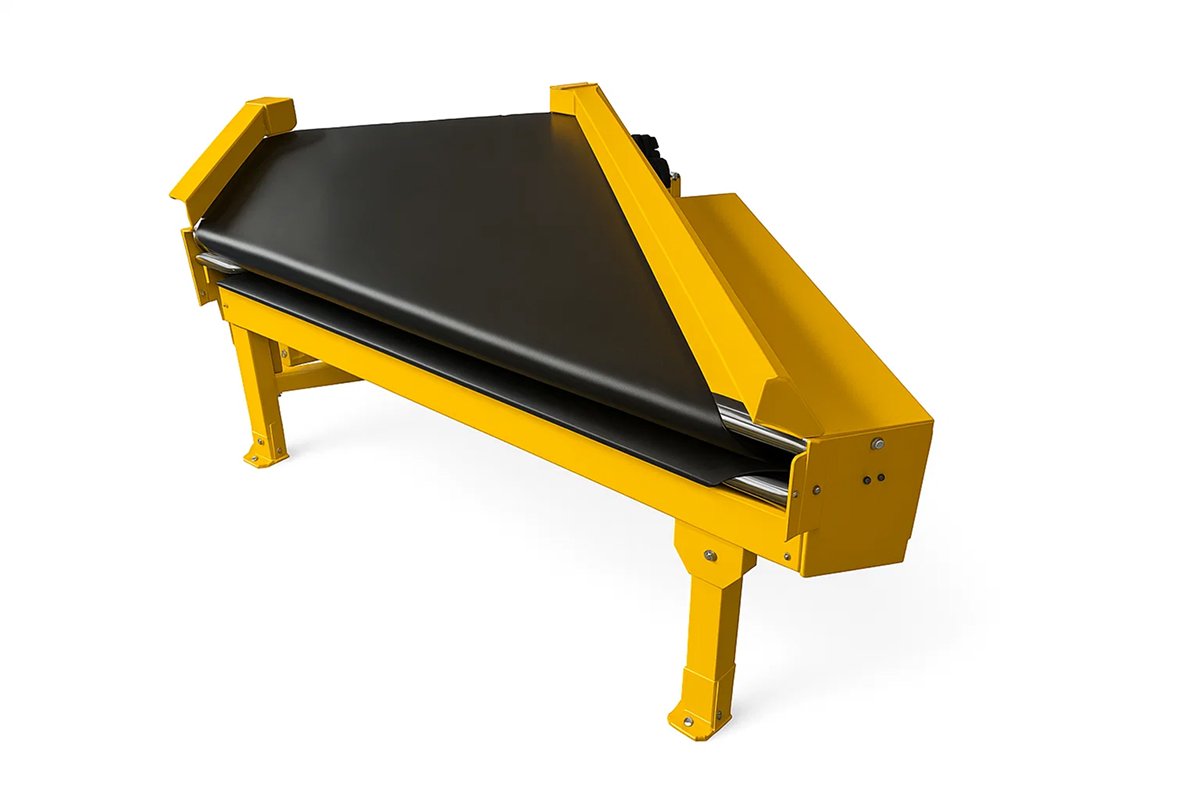

Belt conveyors are continuous transport systems that use a looped belt to move goods along a predetermined path. LEADOR offers a wide portfolio of belt conveyor configurations tailored to various load types, surface requirements, and environmental conditions. Our belt conveyors are ideal for light to medium-duty loads and are especially suited for continuous flows across long distances, inclined paths, or where product stability is essential.

Introduction & Core Benefits

Leador Tech’s Belt Conveyors are the workhorses of modern material handling, providing a continuous, flat, and stable surface for transporting goods. They consist of a continuous loop of durable belt material stretched over two or more pulleys, with one or more powered to move the belt. This fundamental design allows for exceptional versatility in handling a vast array of item types, including packages, polybags, totes, loose items, and even bulk materials (with appropriate belt types). Renowned for their smooth operation, high reliability, and ability to handle inclines/declines, belt conveyors are the preferred choice across warehousing, e-commerce, manufacturing, assembly lines, food processing, and distribution centersBelt Conveyor Types

01. Slider Bed Belt Conveyors

02. Roller Bed Belt Conveyors

03. Accumulation Roller Conveyors

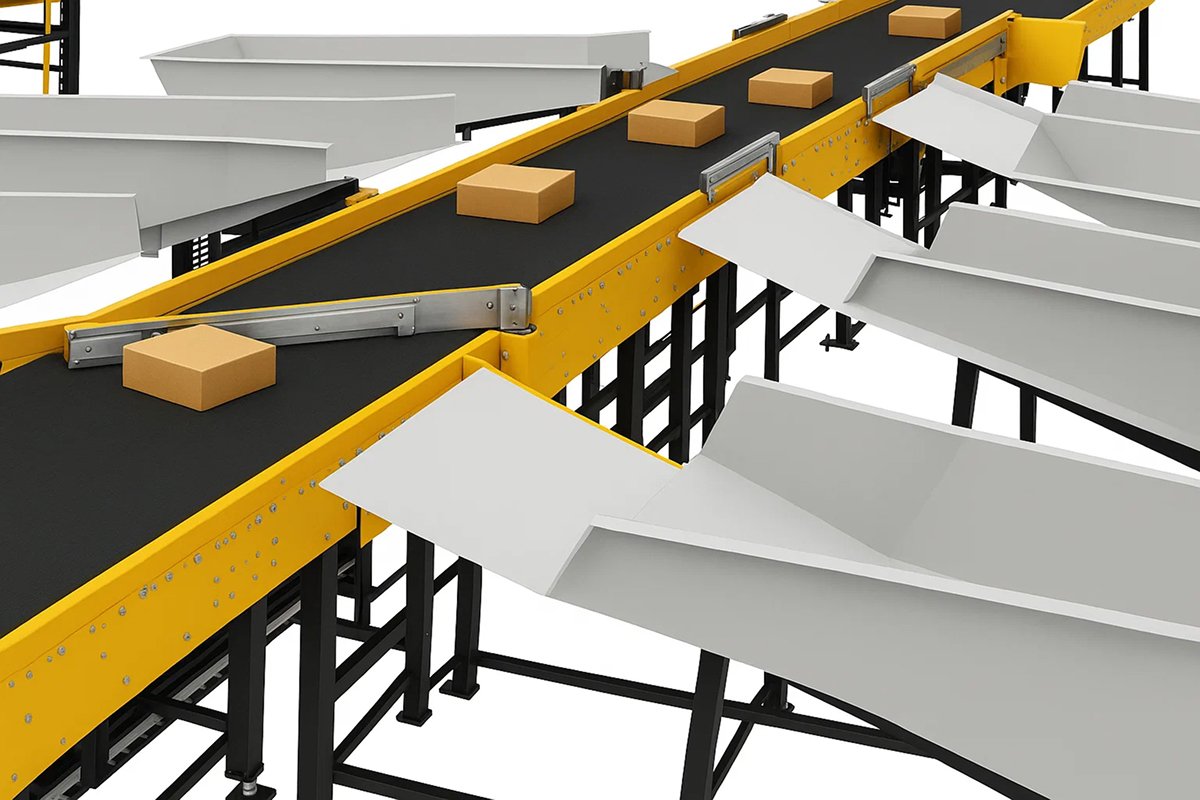

Application Scenarios

E-commerce

High-speed MDR conveyors reduce noise, allow flexible and handle variable carton sizes.

Manufacturing

Chain-driven systems move heavy or irregular parts with positional precision.

Parcel Distribution

Robust merge/diverge control with modular routing allows scaling based on peak periods.

Retail Warehousing

Mixed-use conveyors support picking, packing, and shipping without layout disruptions.

Industries

Belt-driven and stainless rollers ensure quiet, contamination-free movement.

LEADOR’s Roller Conveyor systems are composed of modular sub-systems:

- Straight Conveyors – Main transport lines with optional side guides

- Curved Sections – Enable routing flexibility within tight layouts

- Merge & Diverge Units – Manage multi-line convergence

- Pop-up Transfers – Directional shifts (typically 90°)

- Lift Gates – Allow walk-through access points

- Support Frames – Height-adjustable and anti-vibration design

- Photoelectric Sensors & Control Modules – Real-time item detection and zone logic

- Gravity-fed for passive movement (relying on slope and load weight)

- Chain or belt-driven for continuous powered motion

- Driven by brushless DC motors (MDR), offering zoned actuation and intelligent controls

- In MDR systems, each zone contains a sensor and a motorized roller that activates only when a load is detected — minimizing energy usage, improving safety, and reducing noise.

Technical Specifications

|

Parameter

|

Value Range

|

Engineering Notes

|

|---|---|---|

|

Belt Width |

300 – 1,200 mm |

Match to product dimensions and clearance |

|

Conveyor Speed |

0.2 – 3.0 m/s |

Varies by load type and throughput requirements |

|

Incline Angle |

0° – 30° |

Cleated belts recommended beyond 15° |

|

Load Capacity |

Up to 100 kg/m |

Heavier loads require reinforced frame + belt |

|

Belt Material |

PVC, PU, Rubber, Modular |

Select based on environment and contact surface |

|

Voltage Options |

220V / 380V AC |

Servo and VFD compatible motors available |

Applications & Case Studies

Discover how Leador has empowered businesses to achieve their logistics goals. Explore our detailed case studies showcasing real-world implementations and measurable results