Product Overview

Capture every detail in motion. LEADOR’s Dynamic DWS Systems combine high-speed dimensioning, weighing, and scanning into a single, intelligent module — designed to bring visibility, traceability, and efficiency to fast-moving logistics lines. From parcels to polybags, accuracy meets automation in every scan.

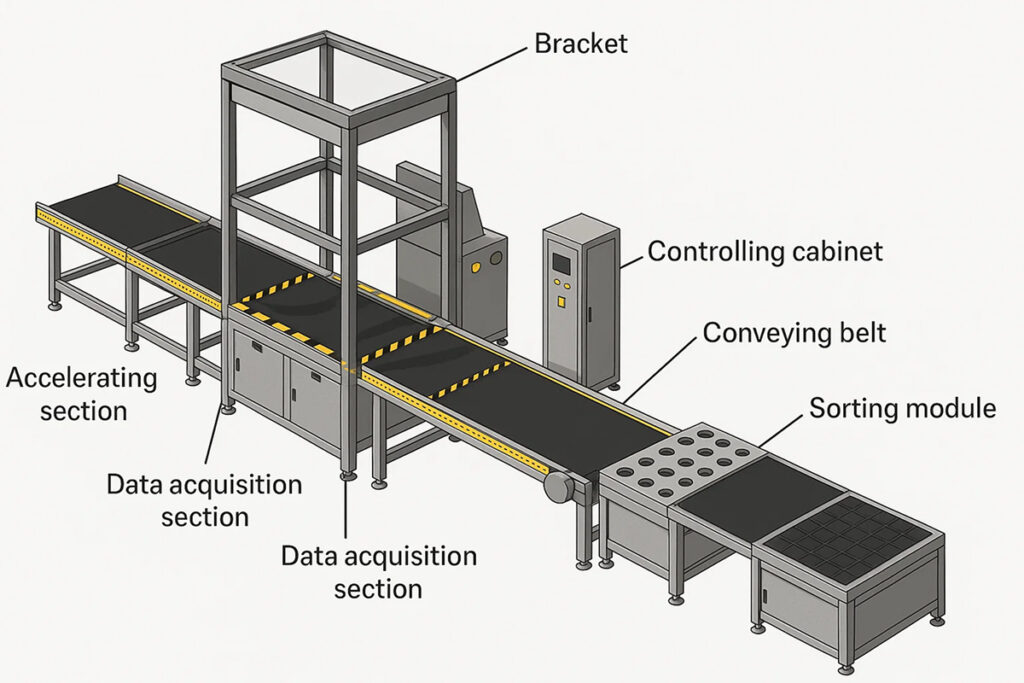

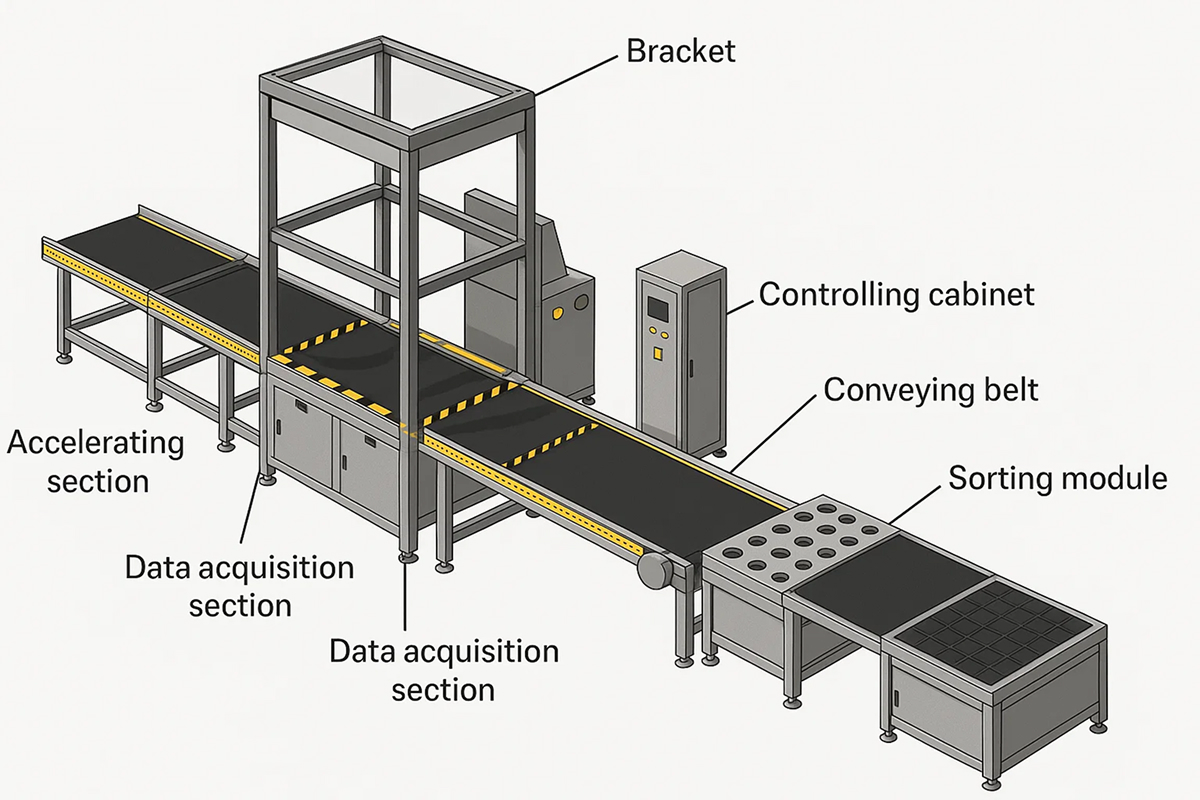

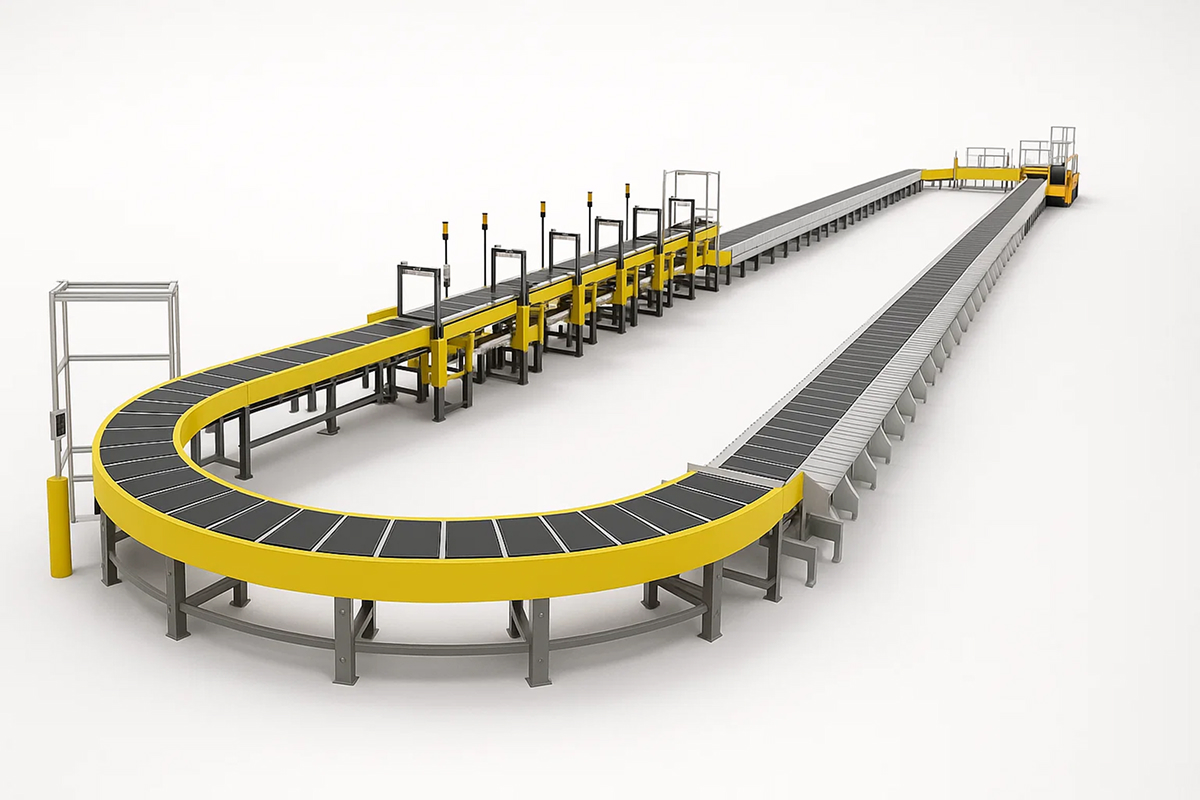

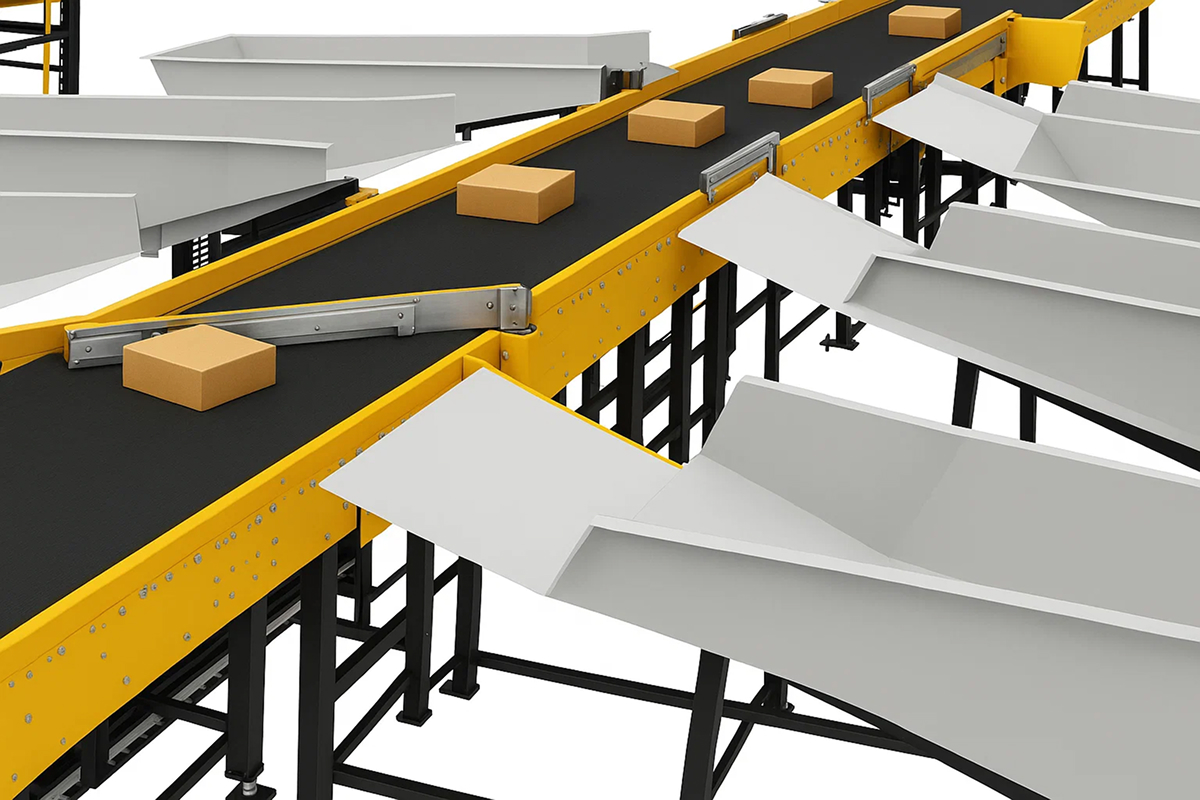

LEADOR’s Dynamic DWS (Dimensioning-Weighing-Scanning) Systems are fully integrated inline units that capture critical parcel data — size, weight, barcode — at high speeds and with high precision. Designed for e-commerce, express logistics, and warehousing applications, our systems support real-time item identification, volume billing, sorting logic, and traceability.

By uniting industrial vision, laser measurement, and weighing sensors in one synchronized unit, DWS transforms passive conveyor lines into data-rich checkpoints.Introduction & Core Benefits

Leador Tech’s Dynamic DWS (Dimensioning, Weighing, and Scanning) Systems are crucial components in modern automated logistics, acting as a high-speed data gateway for every item. These integrated units simultaneously capture an item’s precise dimensions (length, width, height), accurate weight, and all barcode/ID data (1D/2D) as it moves seamlessly along a conveyor. Leveraging advanced laser, camera, and weighing technologies, our DWS systems provide real-time, verifiable data essential for accurate freight billing, optimal load planning, intelligent sortation, and comprehensive traceability. They are indispensable for e-commerce, express parcel, and third-party logistics (3PL) providers.Application Scenarios

Courier & Express Hubs

Automated waybill validation and dimension pricing

E-commerce

SKU tracking and real-time order verification

Distribution Centers

Master data collection for inbound/outbound SKUs

Return Goods Handling

Data acquisition for irregular-shaped items

Load Optimization

Dimension-based container loading and shipment rating

Weighing: An integrated dynamic weighing scale precisely measures the item’s weight as it passes over.

Scanning: High-speed barcode scanners (omnidirectional or fixed-position) or vision systems identify 1D/2D barcodes from various orientations. All data is instantaneously processed by an intelligent control unit and made available for immediate system action and external integration.

Technical Specifications

|

Parameter

|

Value

|

|---|---|

|

Conveyor Speed |

Up to 3.0 m/s |

|

Throughput |

6,000–7,000 items/hour |

|

Weight Range |

100 g – 30 kg |

|

Dimensioning Accuracy |

±5 mm (L/W/H) |

|

Weight Accuracy |

±50 g |

|

Barcode Read Rate |

≥ 99.9% |

|

Data Output Format |

JSON, XML, CSV |

| Power Supply |

220V, 50/60Hz |

Applications & Case Studies

Discover how Leador has empowered businesses to achieve their logistics goals. Explore our detailed case studies showcasing real-world implementations and measurable results