System Introduction

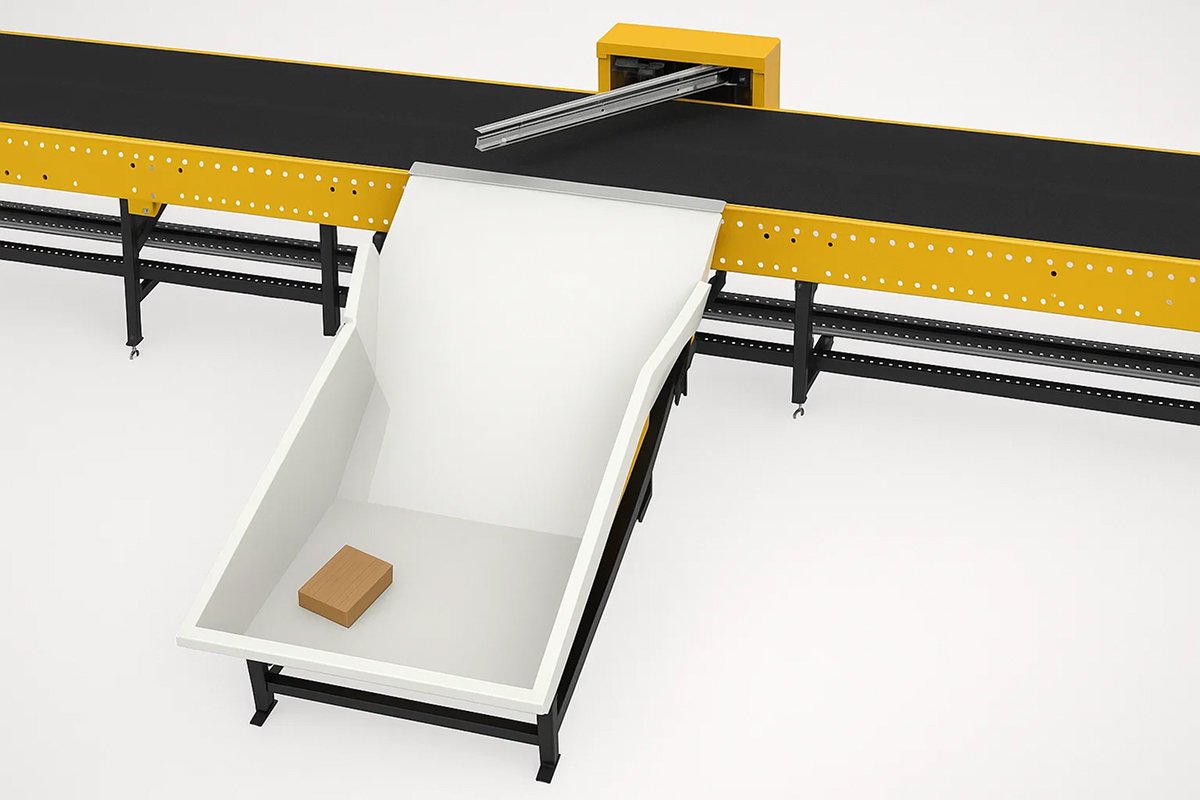

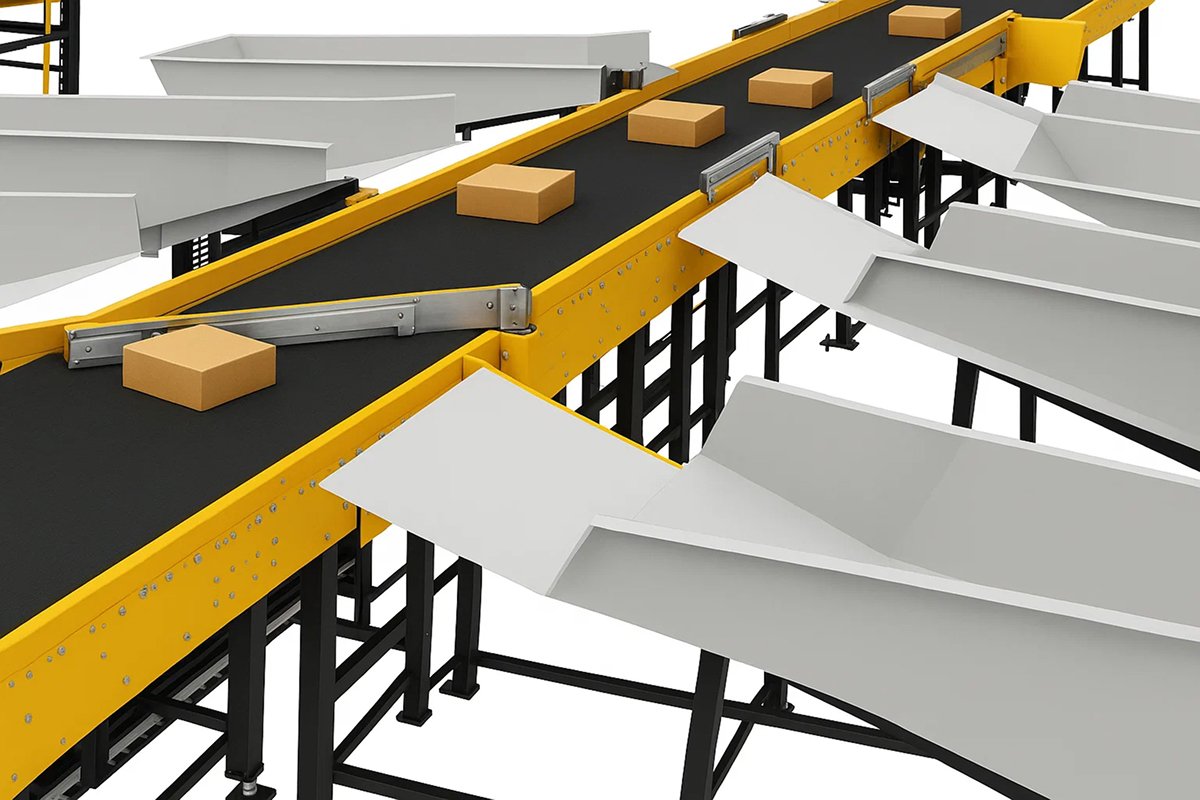

The Swing Arm Sorter is a reliable, mid-speed sorting system that uses pivoting arms to gently push parcels or cartons from a main conveyor to designated outbound lanes. Designed for cost-effective and precise item diversion, this technology is ideal for applications involving uniformly shaped goods where high-impact sorting methods are undesirable.

Discover a cost-effective and highly reliable solution for your sorting needs with Leador Tech’s Swing Arm Sorters. Designed for efficient, gentle, and precise diversion of a variety of items, these compact units offer an ideal balance of performance and affordability. Perfect for applications requiring flexible sortation points on existing conveyor lines in distribution centers, e-commerce operations, and light manufacturing

Application Scenarios

Warehouses

Sorting of boxed literature and soft goods

E-commerce & 3PL

End-of-line diversion of packed orders

Mail & Parcel Sorting

Diversion of mail trays, flat envelopes, mid-sized parcels

Distribution Centers

Store-specific routing of items in mid-volume settings

Pharma & Cosmetics

Low-impact handling of boxed sensitive products

Primary Conveyor Line: The main belt or roller conveyor that the swing arm diverter is mounted onto. (Internal Link to Intelligent Conveyor Systems)

Barcode Scanners/Vision Systems: Integrated upstream for automatic item identification and sorting logic. (Internal Link to Intelligent Vision Systems)

Take-Away Conveyors/Chutes: Adjacent conveyors or gravity chutes designed to receive the diverted items.

PLC Control Systems: The intelligent backbone controlling the precise timing and activation of the swing arm based on sorting data. (Internal Link to PLC & SCADA Control Systems page)

Integration with Warehouse Software: Seamless data exchange with WMS/WCS for order routing, inventory updates, and performance monitoring. (Internal Link to Warehouse Software Solutions page)

Technical Specifications

|

Parameter

|

Value

|

|---|---|

|

Max Throughput |

3,500 items/hour |

|

Divert Angles |

30° or 45° |

|

Max Package Weight |

30 kg |

|

Control Type |

Servo / Pneumatic |

|

Conveyor Type |

Belt or roller |

|

System Noise |

≤ 68 dB |

|

Sort Activation Accuracy |

±10 mm position tolerance |

| Communication Protocol |

Modbus / Profinet / Ethernet |

Applications & Case Studies

Discover how Leador has empowered businesses to achieve their logistics goals. Explore our detailed case studies showcasing real-world implementations and measurable results