Intelligent Vision Systems

See smarter. Act faster. Automate better. In modern warehouses and logistics centers, machine vision is no longer a luxury—it’s a necessity. LEADOR’s Intelligent Vision Systems empower automation processes with real-time visual recognition, precise object tracking, defect detection, barcode scanning, and AI-based decision-making. These systems serve as the “digital eyes” of logistics, integrated across sortation lines, robotic picking stations, conveyor networks, and high-density storage systems. From verifying parcel integrity to guiding robotic arms, vision technology enhances both speed and accuracy.Application Scenarios

LEADOR Intelligent Vision Systems are widely applied in:

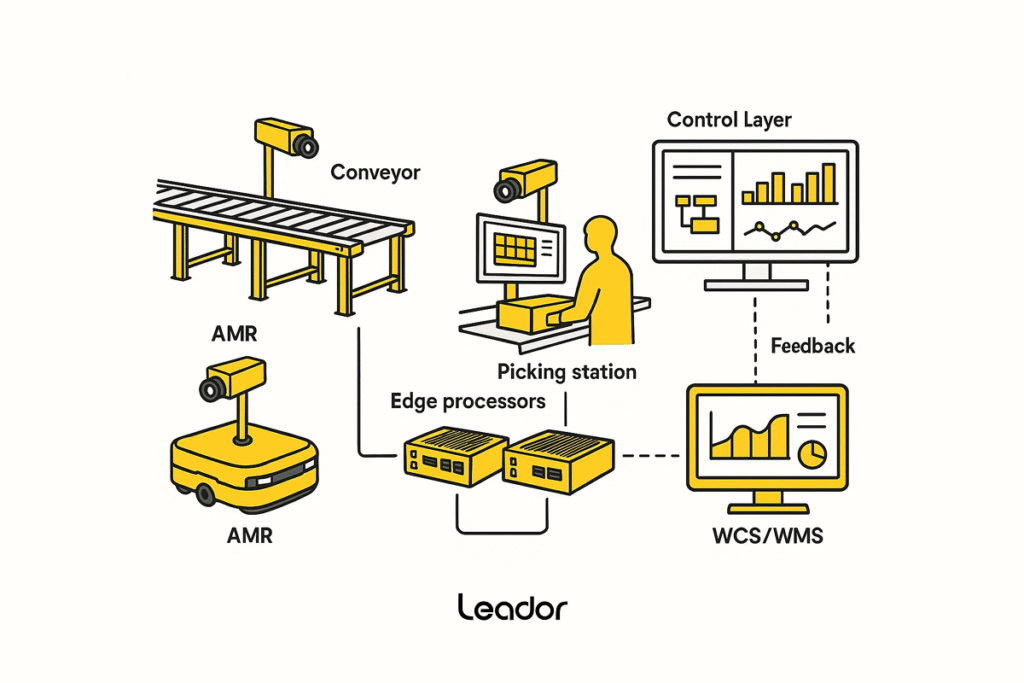

System Structure & Components.

A robust warehouse software environment is typically made up of the following layers.

Critical Technical Specifications

|

Technical Parameter

|

Specification Range

|

|---|---|

|

Max Throughput |

4,000 – 20,000 items/hour |

|

Supported Item Size |

Min: 100×100 mm / Max: 800×800 mm |

|

Weight Range |

0.1 kg – 50 kg |

|

Sorting Accuracy |

≥ 99.99% |

|

Conveyor Speed |

Up to 2.5 m/s |

|

Ambient Operating Temperature |

-10°C to 45°C |

Key Features & Advantages

Systems combine mechanical precision with intelligent control, offering distinct advantages:

Real-time data flow

Inventory, equipment status, and order progress are updated in milliseconds.

Flexible rule engine

Users can configure custom workflows, pick paths, and stock movement strategies.

Multi-language & multi-site support

Ideal for international operations with decentralized warehousing.

Robust error handling

Intelligent alerts, fallback options, and diagnostic logs to handle exceptions.

Cloud-ready or on-premise

Choose from local server deployment or scalable cloud hosting based on IT policy.

Role-based permissions

Ensures data integrity and access control for different operational layers.

Compatibility, Safety & Support

Fill out the form below to download the catalog

Case Study

Discover how Leador has empowered businesses to achieve their logistics goals. Explore our detailed case studies showcasing real-world implementations and measurable results